What is the Best Material for Rice Mill Screens

Choosing the Ideal Material for Rice Mill Screens: A Comparison of Carbon Steel, Mild Steel, Stainless Steel 304, and 201 Selecting the right material for

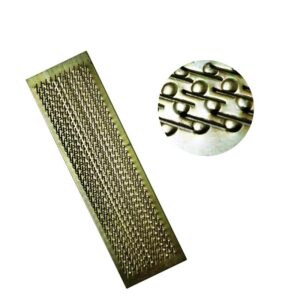

Selecting the right material for rice mill screens is crucial for optimizing performance and longevity. In addition to carbon steel and mild steel, stainless steels 304 and 201 are also popular choices. Each material offers distinct advantages and is suitable for different applications. Here’s a detailed comparison to help you make an informed decision.

Carbon steel is known for its high strength and durability due to its significant carbon content. It is well-suited for heavy-duty applications where strength is a priority.

Key Benefits of Carbon Steel for Rice Mill Screens:

Drawback: Carbon steel is more prone to rust and corrosion, often requiring additional coatings or treatments to protect against environmental factors.

Mild steel, also known as low carbon steel, contains a lower amount of carbon, making it more malleable and easier to shape. It is a versatile option for various rice milling applications.

Advantages of Mild Steel for Rice Mill Screens:

Drawback: Mild steel may not offer the same level of strength and durability as carbon steel, making it less suitable for extremely heavy-duty applications.

Stainless Steel 304 is a high-grade stainless steel known for its excellent corrosion resistance and high temperature tolerance. It is ideal for environments where exposure to moisture and chemicals is a concern.

Key Benefits of Stainless Steel 304 for Rice Mill Screens:

Drawback: Stainless Steel 304 is relatively expensive, but its longevity and low maintenance requirements often justify the cost for long-term investments.

Stainless Steel 201 is a more affordable stainless steel option, offering good corrosion resistance at a lower cost compared to 304.

Advantages of Stainless Steel 201 for Rice Mill Screens:

Drawback: Stainless Steel 201 has slightly lower corrosion resistance compared to 304, which may limit its use in highly corrosive environments.

Choosing the right material for your rice mill screens depends on your specific operational needs and budget. Carbon Steel offers superior strength and durability for heavy-duty applications; Mild Steel provides excellent malleability and corrosion resistance at a lower cost; Stainless Steel 304 delivers top-notch corrosion resistance and high temperature tolerance, making it ideal for harsh environments; while Stainless Steel 201 balances cost and corrosion resistance effectively.

Understanding the properties of these materials will help you select the most suitable option to enhance the efficiency and lifespan of your rice milling equipment. For more information or assistance with selecting the best materials for your rice mill screens, feel free to contact us. We’re here to provide expert advice and support.

Most Popular

Choosing the Ideal Material for Rice Mill Screens: A Comparison of Carbon Steel, Mild Steel, Stainless Steel 304, and 201 Selecting the right material for

Always Breaking? Explore Superior Screening Solutions Are you searching for reliable agricultural machine screens to enhance your farm machinery? Look no further! Our advanced sieve

Understanding Hammer Mill Screens: Types, Functions, and Benefits How Hammer Mill Screens Work Hammer mill screens are critical components in the grinding and milling processes

8 Things You Need To Know There are a total of 2 steps for What does a hammer mill do, follow along with the editor

There are a total of 2 steps for What does a hammer mill do, follow along with the editor to take a look! Table of

Table of Contents Milling process for rice Feeding and Cleaning So, What is the milling process for rice? First let’s see grain cleaning machine, also

8437.90 or 8437.80 What is the Hs code for rice mill screen? The Hs code for rice mill screens can vary depending on the specific type

Latest News

Contact Us

Address

Wensheng south RD, Yueyang, Hunan, CN

Email Us

silvia@agro-greengo.com

Call/ WhatsApp

+86 15115027808