Table of Contents

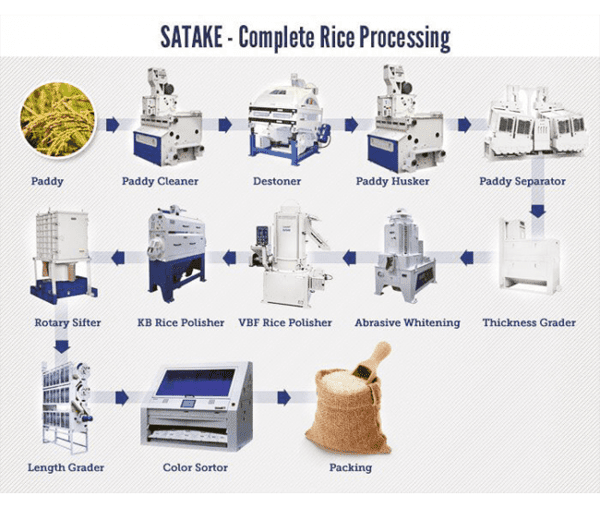

Milling process for rice

Feeding and Cleaning

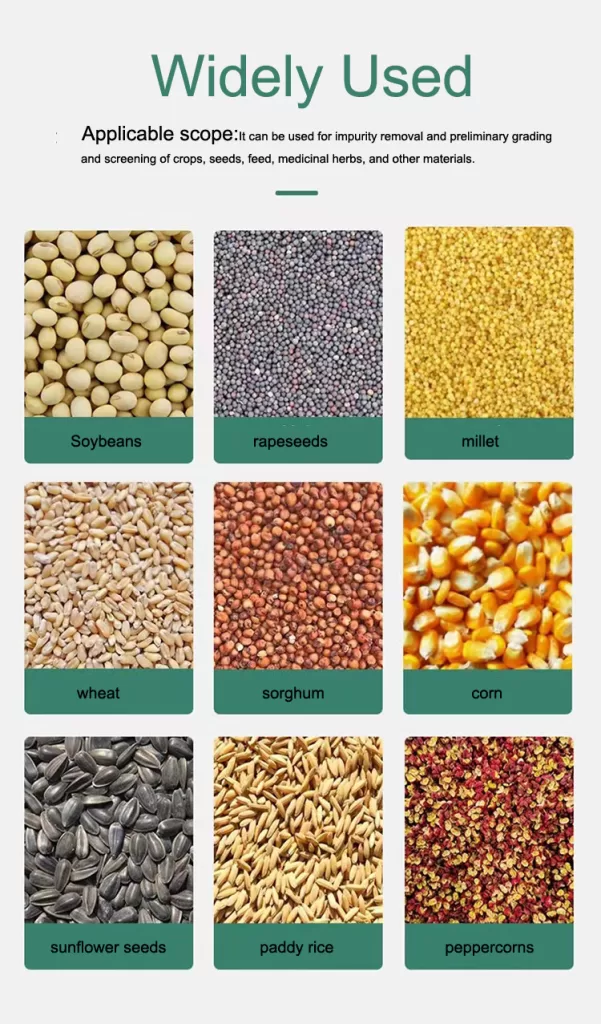

So, What is the milling process for rice? First let’s see grain cleaning machine, also known as a grain cleaning equipment or grain impurity removing machine, is an agricultural machinery used for processing grains. Its main function is to remove impurities from raw grains, improving the quality and purity of the grains. The rice is screened and cleaned to remove impurities, stones, straw, and other debris.

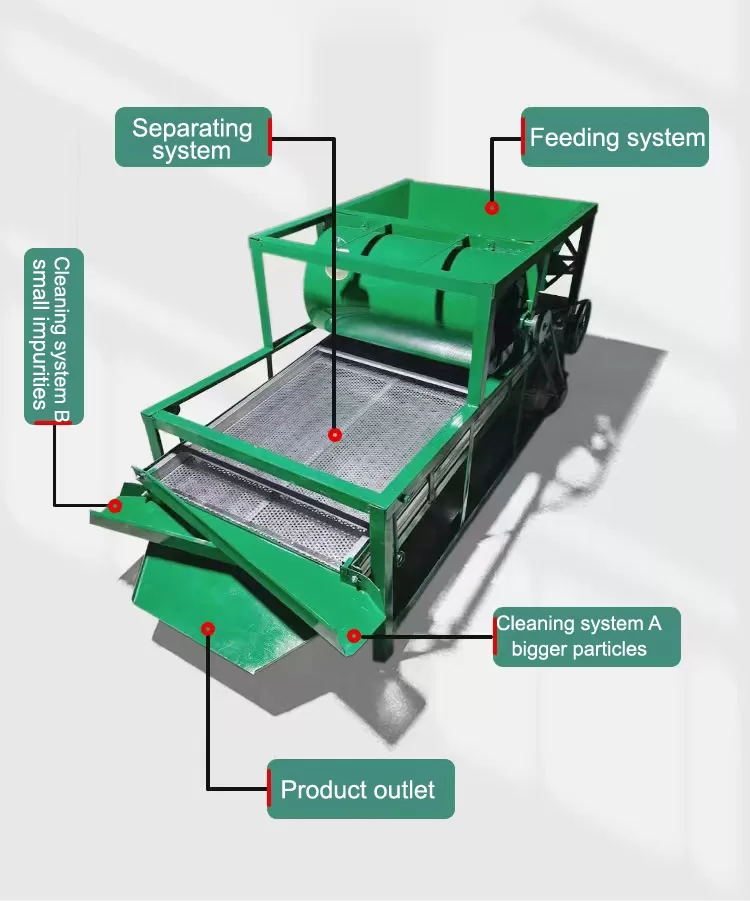

A grain cleaning machine typically consists of several components, including a feeding system, a separating system, and a cleaning system. Firstly, the grains are fed into the feeding system and then conveyed to the separating system through a conveyor belt or pipeline. The separating system utilizes various methods such as perforated sheets, sieves, airflow, or vibration to separate impurities such as stones, sand, branches, straw, weeds, and foreign grains from the grains. The separation process can be adjusted based on the size, weight, and shape of the impurities. This emphasizes the importance of rice milling

Once the separation is completed, the grains enter the cleaning system, which primarily removes small impurities such as dust, debris, and bran from the grains through methods like blowing or suction. The cleaning system is typically equipped with fans, filters, and collection devices to ensure the effective removal of impurities and collect and handle the removed impurities.

Grain cleaning machines play a crucial role in agricultural production, as they can improve the quality and market competitiveness of grains. By removing impurities, the impurity content and impurity rate of grains can be significantly reduced, thereby reducing losses and occurrences of pests and diseases during storage. Additionally, high-quality grains meet consumers’ demands for food safety and nutrition.

It is important to note that the performance and processing capacity of grain cleaning machines may vary depending on the model and specifications, and the choice of a specific grain cleaning machine should consider specific needs and requirements. Furthermore, regular maintenance and cleaning are necessary when using a grain cleaning machine to ensure its proper operation and prolong its service life.

The perforated sheet

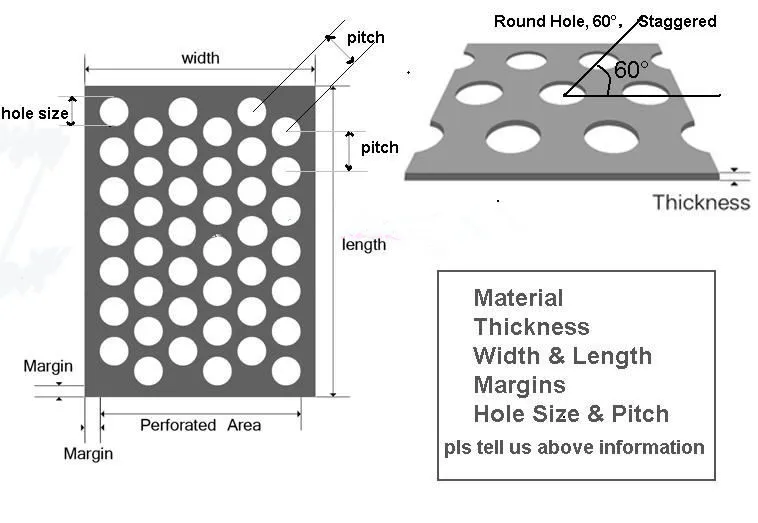

The perforated sheet is an important component in a grain-cleaning machine used for separating grains from impurities.

In a grain cleaning machine, the sieve screen works by filtering and separating larger impurities from the grains. When the grains pass through the sieve screen, the impurities are blocked on the screen, while smaller grain particles pass through the sieve holes.

The selection and maintenance of the sieve screen are crucial for the performance and effectiveness of the grain cleaning machine. Regular cleaning and replacement of worn-out sieve screens ensure the proper functioning of the machine and improve the quality and purity of the grains.

Considerations when selecting sieve screens:

(1)Size and specifications: Choose the appropriate sieve screen size and specifications based on your specific needs to ensure effective filtration of the target material.

(2)Material selection: Consider the working environment and the nature of the materials to be sieved. Choose suitable materials such as stainless steel or polymers to ensure durability and safety.

Stainless steel perforated sheet is widely used in the removal of impurities from grains and seeds.

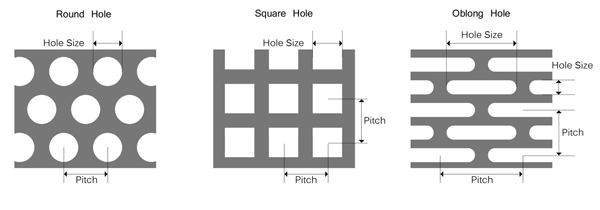

(3)Mesh shape: Select the right mesh shape according to the shape and size of the materials to be sieved, to prevent clogging or material bypass.

Here are some suggestions for sieve shape:

(4)Screen quality: Check the manufacturing process and quality of the rice mill sieve screen during the selection process to ensure it is free from defects and has a longer service life.

- Heat Treatment: Heat treatment involves subjecting the sieve plate material to high-temperature processing to eliminate internal stresses and improve hardness and wear resistance. This increases the strength and durability of the sieve plate, effectively extending its service life, and enhancing its ability to resist wear, impact, and corrosion.

- Regular Aperture: Regular aperture refers to a consistent size, spacing, and shape of the openings when manufacturing the sieve plate. This design makes the sieve plate more stable during the screening process, reducing localized stress concentration and lowering the wear rate. Additionally, regular aperture facilitates regular cleaning, prevents blockages, maintains efficient screening, and further extends the service life.

(5)Brand reputation: Choose manufacturers or suppliers with a good reputation to ensure product quality and after-sales service.

Rice Milling overview-SATAKE

Related Posts

What is the Best Material for Rice Mill Screens

Choosing the Ideal Material for Rice Mill Screens: A Comparison of Carbon Steel, Mild Steel, Stainless Steel 304, and 201 Selecting the right material for

What are the different methods of surface hardening?

Always Breaking? Explore Superior Screening Solutions Are you searching for reliable agricultural machine screens to enhance your farm machinery? Look no further! Our advanced sieve

How Hammer Mill Screens Work

Understanding Hammer Mill Screens: Types, Functions, and Benefits How Hammer Mill Screens Work Hammer mill screens are critical components in the grinding and milling processes

What is the crushing and screening process

8 Things You Need To Know There are a total of 2 steps for What does a hammer mill do, follow along with the editor

What does a hammer mill do?

There are a total of 2 steps for What does a hammer mill do, follow along with the editor to take a look! Table of

What is milling process for rice?

Table of Contents Milling process for rice Feeding and Cleaning So, What is the milling process for rice? First let’s see grain cleaning machine, also