- 86-15115027808

- Silvia@agro-greengo.com

- Yueyang Hunan, CN

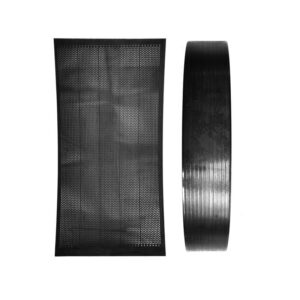

6N40 Mini rice mill screen

Key Features

1. Compatible with the 6n40 rice mill for versatile use.

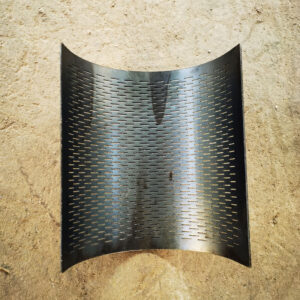

2. Uniform and standardized perforations ensure the integrity of rice grains.

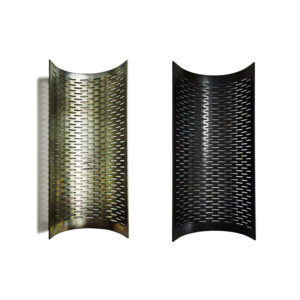

3. Various materials like manganese steel and stainless steel to suit different preferences.

4. Specially heat-treated for increased hardness and wear resistance, ensuring long-lasting performance.

5. Proud supplier to Lazada and Shopee sellers.

6. MOQ: 5PCS

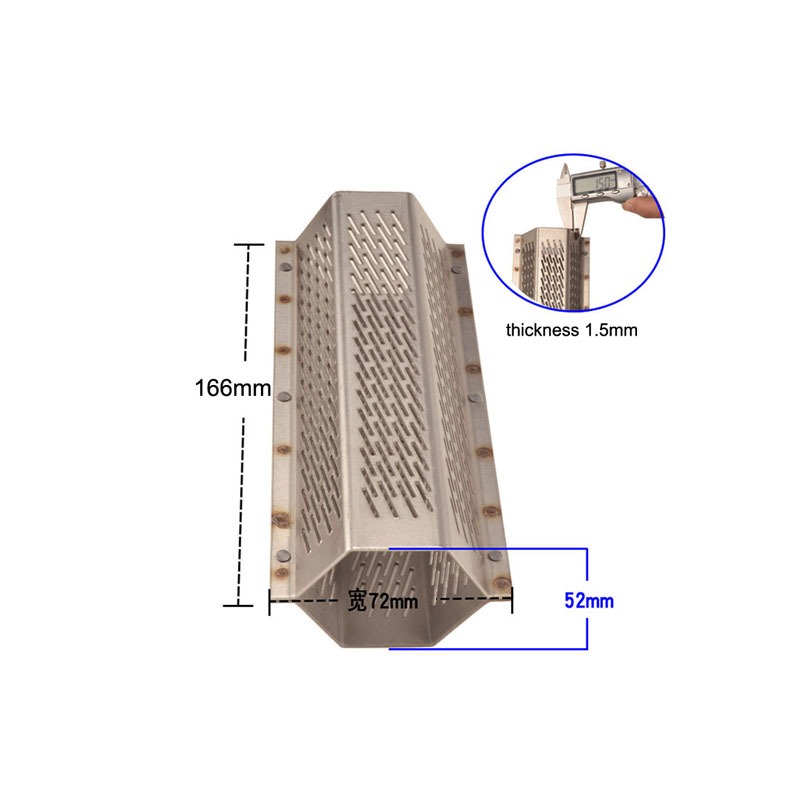

Size: 166×52(72)×1.5/2.0thickness

Table of Contents

Description

6n40 mini rice mill screen

Rice mill screen sieves are like filters in rice processing, removing unwanted bits to make high-quality rice. They come in different sizes, are durable, and help ensure efficient Rice milling equipment

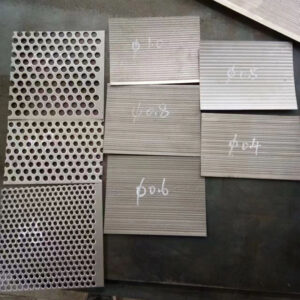

Hole size:

0.7/0.9mm for millet

1.0/1.2mm for rice

Methods to Extend the Service Life of the Rice Sieve:

Loosen the discharge outlet slightly.

Sift through the grains, removing stones or screws.

Manganese steel screen: 1000~2000KG

Stainless steel screen: 1500~2500KG

6 Key Features

1. Compatible with the 6n40 rice mill for versatile use.

2. Uniform and standardized perforations ensure the integrity of rice grains.

3. Various materials like manganese steel and stainless steel to suit different preferences.

4. Specially heat-treated for increased hardness and wear resistance, ensuring long-lasting performance.

5. Proud supplier to Lazada and Shopee sellers.

6. MOQ: 5PCS

Our advantages

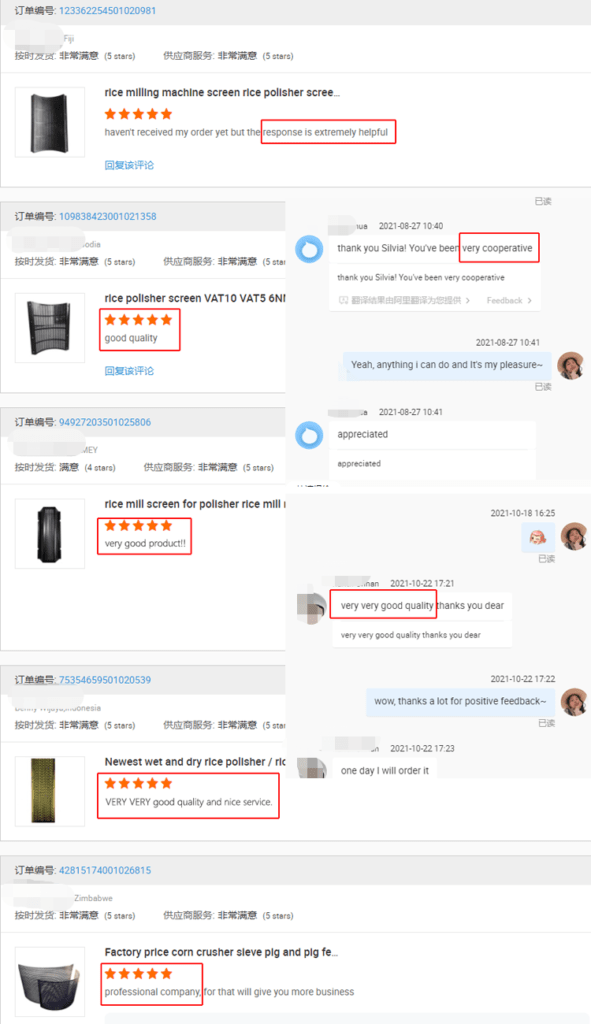

Feedback from clients

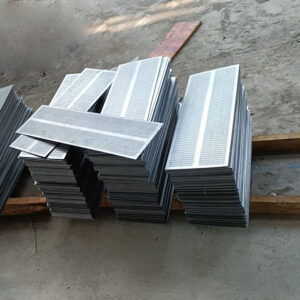

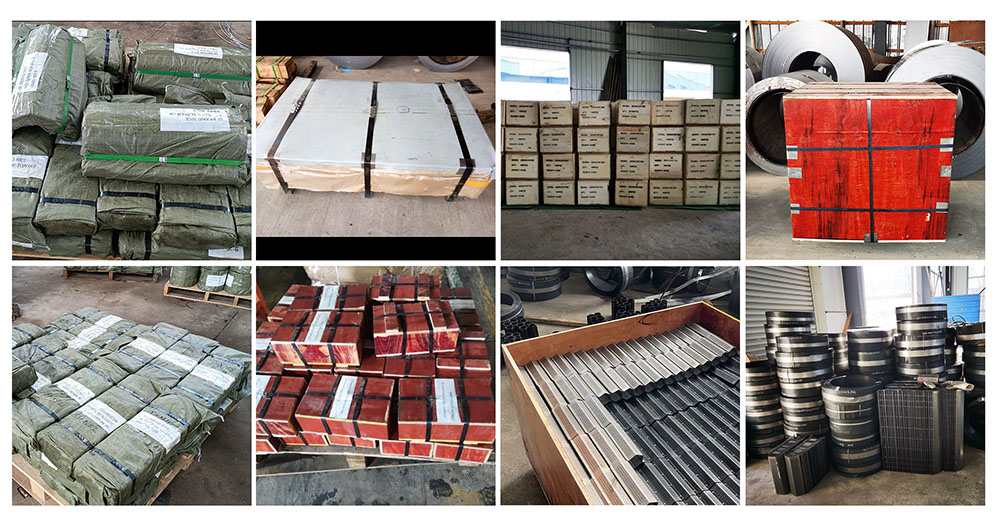

Packaging

How to place an order?

Select the Product:

- Choose the desired items from store.

Place an Order:

- Fill in the order form on our website with the necessary details.

Payment:

- Select a payment method and complete the transaction.

Order Confirmation:

- Receive and confirm the order details.

Shipping:

- We will prepare and ship the items, providing a tracking number.(by air)

- Send it to your agent in China.(by sea or air)

Logistics and Transport:

- Track the shipment to estimate the arrival time.

Customs Processing:

- The items may undergo customs processing upon arrival, and import duties may apply.

Delivery and Receipt:

- Receive the items and pay any additional fees if required.

Inspection:

- Ensure the items are in good condition and meet the specified requirements.

Feedback and After-Sales:

- Provide feedback on the shopping experience and contact us if issues arise.

Related Posts

What is the purpose of a rice mill?

The purpose of a rice mill is to process raw paddy rice into polished rice ready for consumption.

The purpose of a rice mill is to process raw paddy rice harvested from fields into polished rice ready for consumption. This involves several stages of processing to remove the outer husk, bran layers, and impurities from the rice grains. The primary objectives of a rice mill include:

Dehusking: Removing the outer husk from the paddy rice to produce brown rice. This step is crucial as the husk is inedible and must be removed before consumption.

Whitening: Further refining the brown rice to remove the bran layers, resulting in polished white rice. This process enhances the appearance, texture, and taste of the rice.

Grading and Sorting: Sorting rice grains based on size, shape, and quality criteria to separate broken grains, whole grains, and other defects. This ensures consistency and uniformity in the final product.

Cleaning: Removing impurities such as stones, straw, dust, and other debris from the rice grains to improve quality and safety.

Polishing: Optional but common step to give the rice a shiny appearance and improve its marketability. This process involves friction to remove the outer layer of the rice grain.

Quality Control: Monitoring and maintaining quality standards throughout the processing stages to ensure the final product meets consumer expectations in terms of taste, texture, appearance, and hygiene.

Packaging and Distribution: Packaging the polished rice into suitable containers for distribution to consumers, wholesalers, retailers, or other markets.

Overall, the purpose of a rice mill is to transform raw paddy rice into high-quality polished rice that is safe, nutritious, and desirable for consumption. This process adds value to the raw agricultural product and plays a crucial role in the global food supply chain, providing a staple food source for millions of people worldwide.

You may also like

Address

Wensheng south RD, Yueyang, Hunan, CN

Email Us

silvia@agro-greengo.com

Call/ WhatsApp

+86 15115027808