- 86-15115027808

- Silvia@agro-greengo.com

- Yueyang Hunan, CN

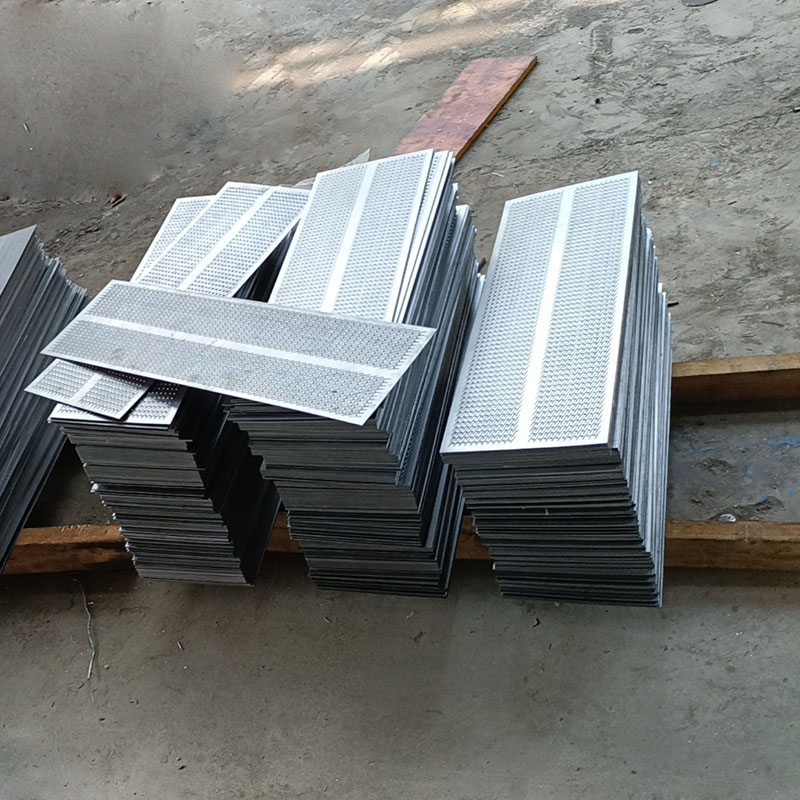

Rice mill screen manufacturer

Product Name: rice mill screen manufacturer

Thickness: rice mill screen:1.0-2.0mm; hammer mill screen: 0.3-5.0mm

Hole size: as your request

Size: Fully customizable.

Material: Carbon steel, SS201, SS304

Packaging: Woven bags, wooden boxes, pallets, or custom.

Table of Contents

Description

Hs code for rice mill screen

The Harmonized System (HS) code for rice mill screens may vary slightly depending on the specific material and design of the screens. However, generally, rice mill screens fall under HS code 843790, which covers parts of machinery used in the milling industry or for the working of cereals or dried leguminous vegetables, including rice mill screens.

How to changing milling sieve mesh

Changing milling sieve mesh involves several steps:

Shutdown: Ensure the milling equipment is turned off and disconnected from power to prevent accidents during the process.

Access: Open the housing or access panel to reach the milling sieve area.

Removal: Carefully remove the existing sieve mesh from its position, taking note of any clips, screws, or fasteners securing it in place.

Cleaning: Before installing the new sieve mesh, thoroughly clean the area to remove any debris or residues that may affect the milling process.

Installation: Align the new sieve mesh properly according to the equipment specifications, ensuring it fits securely and snugly in place.

Secure: If necessary, use clips, screws, or other fasteners to secure the new sieve mesh in its position, ensuring it remains stable during operation.

Testing: After installation, perform a test run to ensure the milling equipment operates smoothly and the new sieve mesh functions correctly.

Maintenance: Regularly inspect and clean the milling sieve mesh to prevent clogging and maintain optimal performance.

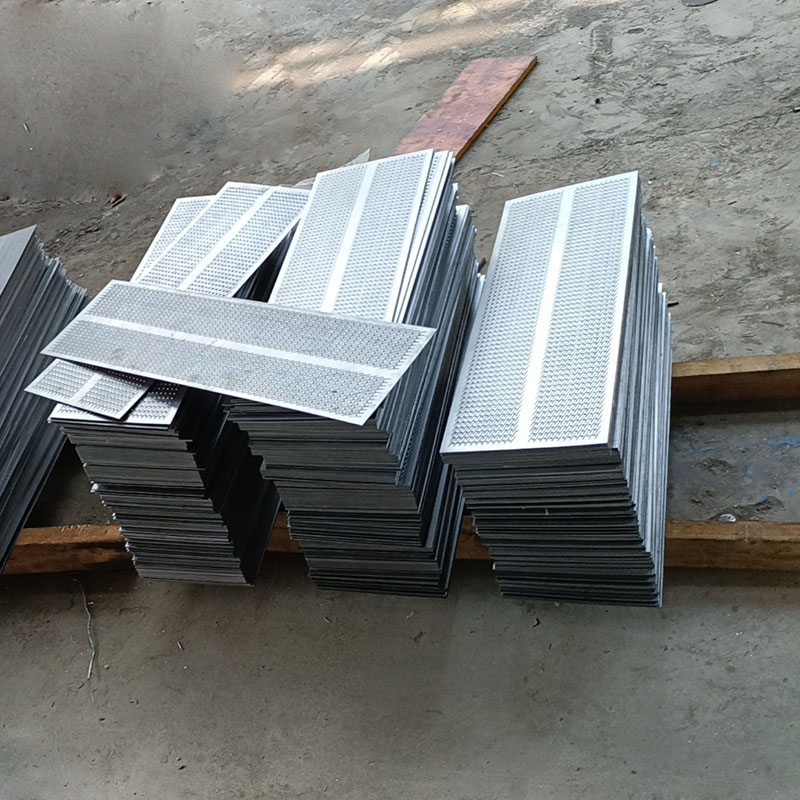

How to measure the screen of rice mills? Rice mill screen manufacturer

To measure the rice mill screen, follow these steps:

- Flatten the perforated steel sheet to ensure it lies completely flat.

- Utilize a centimeter ruler to precisely measure both the length and width of the rice mill screen.

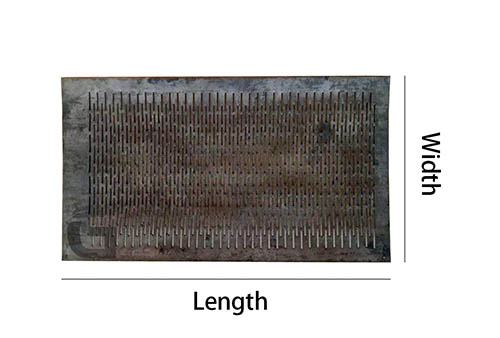

Packaging

How to place an order?

Product Selection:

- Browse through our store and select the desired items.

Order Placement:

- Fill out the order form on our website, providing all necessary details for smooth processing.

Payment Options:

- Choose a convenient payment method and complete the transaction securely.

Order Confirmation:

- Upon submission, you’ll receive a confirmation email detailing your order. Review the information to ensure accuracy.

Shipping Methods:

- We offer two shipping options:

- Air Shipping: Swift delivery with a tracking number provided for real-time updates.

- Sea or Air Shipping to Your Agent in China: For bulk orders or specific requirements.

- We offer two shipping options:

Logistics and Tracking:

- Use the provided tracking number to monitor the progress of your shipment and estimate its arrival time.

Customs Clearance:

- Please note that your items may undergo customs processing upon arrival, and import duties may be applicable as per regulations.

Delivery and Receipt:

- Upon arrival, receive your items and ensure their condition. Any additional fees required for delivery should be settled at this stage.

Quality Assurance:

- Thoroughly inspect the received items to ensure they meet your expectations and specifications.

Feedback and Support:

- We value your feedback! Please share your shopping experience with us, and don’t hesitate to reach out if you have any questions or concerns. Our after-sales support team is here to assist you every step of the way.

FAQ

Q: What quality assurance measures are implemented for your products?

A: Our products are meticulously crafted from high-quality high-carbon steel or stainless steel and undergo rigorous heat treatment processes to ensure superior quality. We stand behind the quality of our products, offering a comprehensive quality assurance guarantee.

Q: How do I determine the most suitable product for my needs?

A: Simply provide us with your machine model or specifications, and our expert team will guide you in selecting the ideal product. Alternatively, you can refer to the product manual for precise specifications. If you’re uncertain about the details, share your requirements with us, and we’ll recommend the most suitable sieve tailored to your needs.

Q: What payment methods do you accept?

A: We offer flexible payment options, including T/T (Telegraphic Transfer), Western Union, and MoneyGram, ensuring convenience and security for our customers.

Q: What is the typical delivery time for orders?

A: Upon order confirmation, small orders can be shipped within 7-15 days via air, while bulk orders may take approximately 30-60 days for delivery via air or sea. We prioritize timely delivery to ensure your satisfaction.

Q: Can I request customization for my order?

A: Yes, we understand that each customer’s needs may vary. We offer customization options to tailor our products to your specific requirements. Contact us to discuss your customization needs, and we’ll work closely with you to fulfill your request.

Address

Wensheng south RD, Yueyang, Hunan, CN

Email Us

silvia@agro-greengo.com

Call/ WhatsApp

+86 15115027808