What is the Best Material for Rice Mill Screens

Choosing the Ideal Material for Rice Mill Screens: A Comparison of Carbon Steel, Mild Steel, Stainless Steel 304, and 201 Selecting the right material for

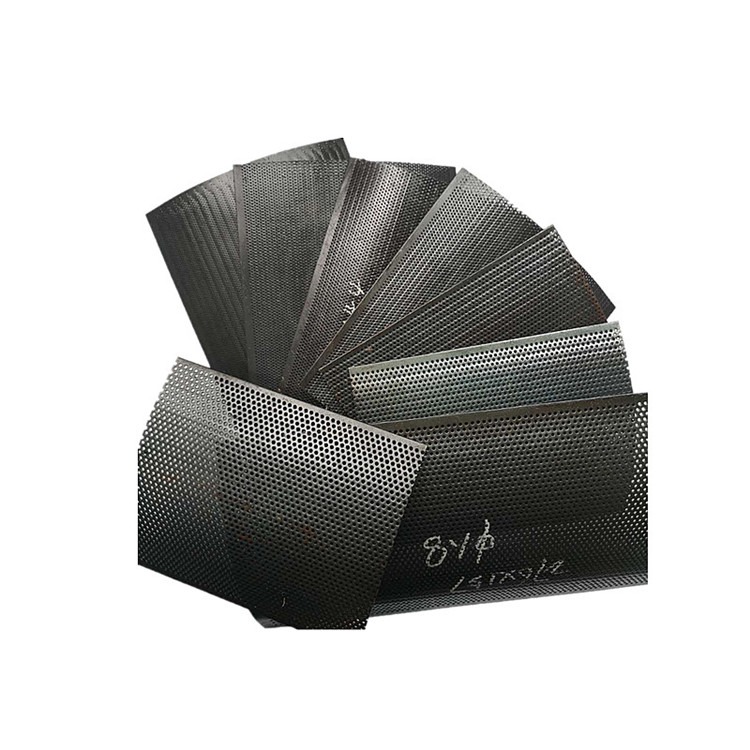

Product Name: Powder Mill Screen

Thickness: Available options from 0.3mm to 5.0mm, adaptable to your specific requirements.

Size: Customizable to suit your needs.

Material: Choose from carbon steel, SS201, SS304, or customized materials to fulfill your specifications.

Packaging: Options include woven bags, wooden boxes, pallet packing, or tailored to your preferences.

Choosing the Ideal Material for Rice Mill Screens: A Comparison of Carbon Steel, Mild Steel, Stainless Steel 304, and 201 Selecting the right material for

Always Breaking? Explore Superior Screening Solutions Are you searching for reliable agricultural machine screens to enhance your farm machinery? Look no further! Our advanced sieve

Understanding Hammer Mill Screens: Types, Functions, and Benefits How Hammer Mill Screens Work Hammer mill screens are critical components in the grinding and milling processes

8 Things You Need To Know There are a total of 2 steps for What does a hammer mill do, follow along with the editor

There are a total of 2 steps for What does a hammer mill do, follow along with the editor to take a look! Table of

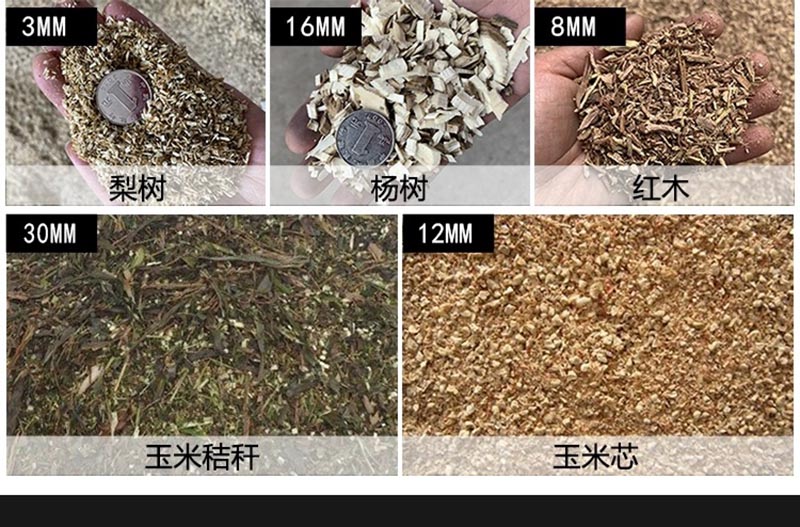

Powder mill screens and hammer mill screens are essential components used in the processing of various materials. Here’s how they’re utilized:

Powder Mill Screens:

Hammer Mill Screens:

Applications of Powder Mill Screens and Hammer Mill Screens:

Overall, powder mill screens and hammer mill screens play critical roles in various industries by facilitating size reduction, particle separation, and product uniformity in material processing operations.

Select the Product:

Place an Order:

Payment:

Order Confirmation:

Shipping:

Logistics and Transport:

Customs Processing:

Delivery and Receipt:

Inspection:

Feedback and After-Sales:

Q: What quality assurance do you offer for your products?

A: Our products are meticulously crafted from premium-grade high-carbon steel or stainless steel and undergo advanced heat treatment processes to ensure outstanding quality. Rest assured, all our products come with a comprehensive quality assurance guarantee.

Q: How can I choose the most suitable product?

A: It’s simple! Just provide us with your machine model or specifications, and we’ll guide you in selecting the perfect product. Alternatively, you can consult the product manual to identify the exact model you need. If you’re uncertain about the specifics, share your requirements with us, and we’ll recommend the most suitable sieve for your application.

Q: What payment methods do you accept?

A: We typically accept payments via T/T (Telegraphic Transfer), Western Union, or MoneyGram for your convenience.

Q: What is your delivery time?

A: Upon order confirmation (via air or sea), small orders can be shipped within approximately 7-15 days, while bulk orders typically ship within 30-60 days. Rest assured, we strive to deliver your products promptly and efficiently.

Address

Wensheng south RD, Yueyang, Hunan, CN

Email Us

silvia@agro-greengo.com

Call/ WhatsApp

+86 15115027808