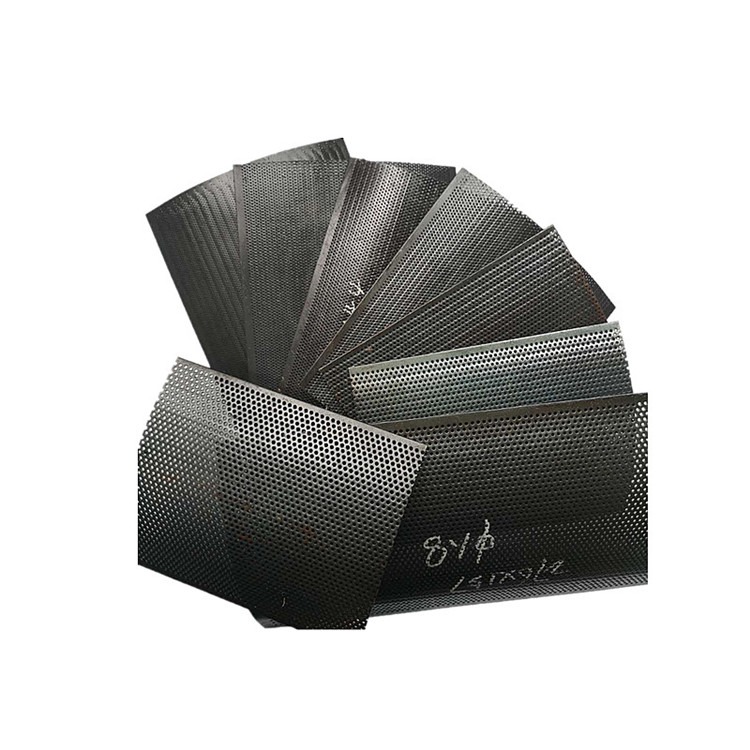

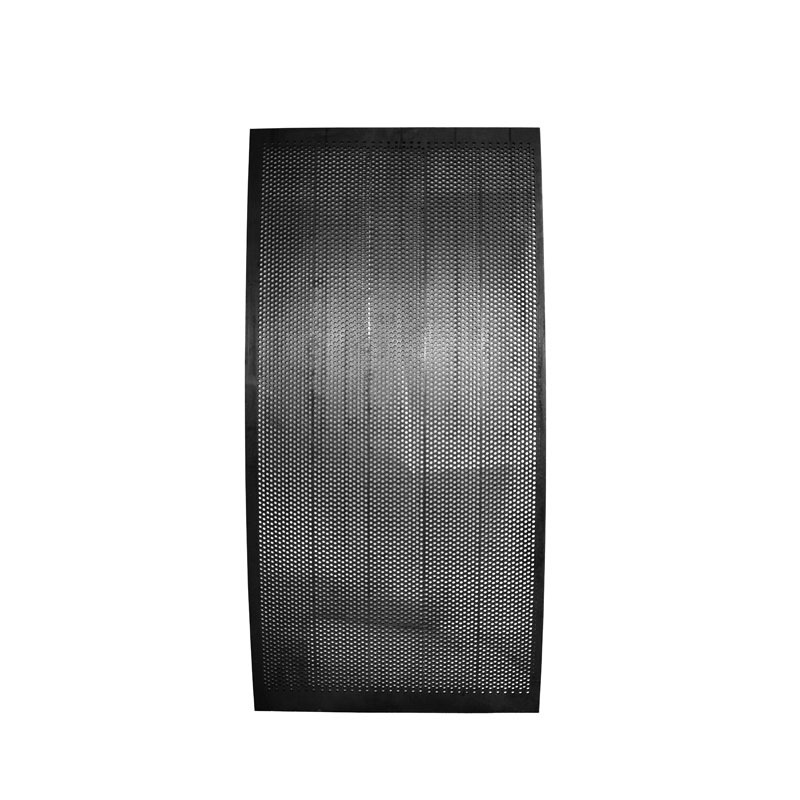

Hammer mill screen types

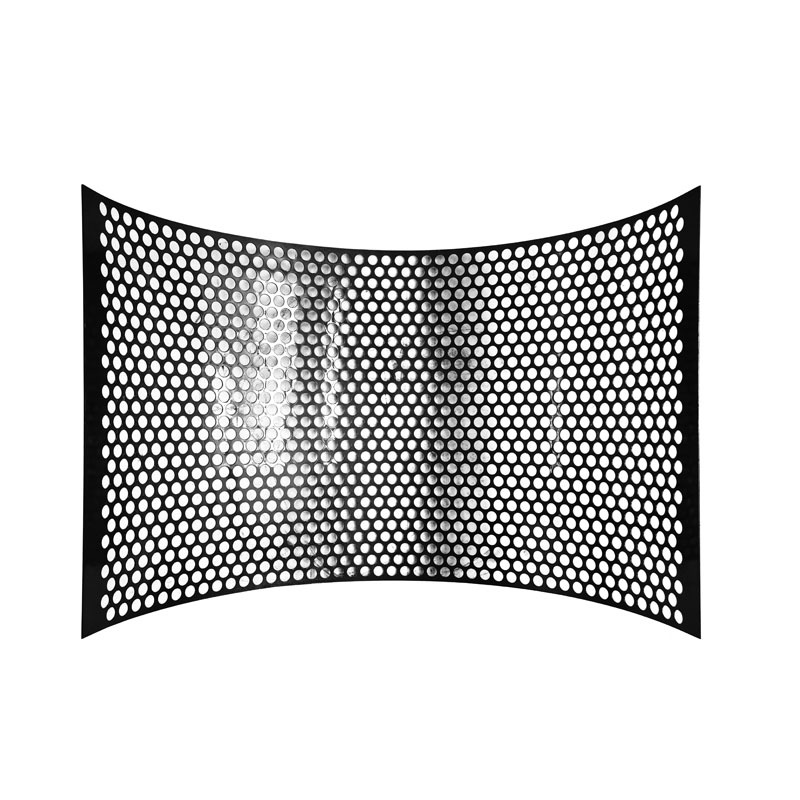

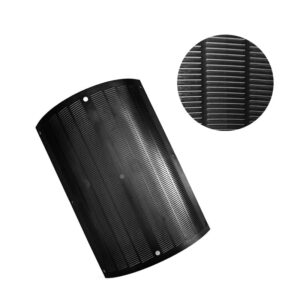

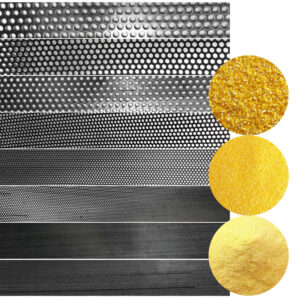

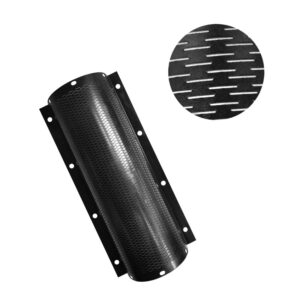

Hammer mill screen types refer to the various configurations and designs of screens used in hammer mills, which are machines used for grinding and pulverizing materials into smaller particles. These screens come in different shapes, sizes, and configurations, each designed to suit specific grinding applications and particle size requirements. Common types of hammer mill screens include perforated screens, wire mesh screens, and bar grates, each offering unique benefits in terms of particle size control, throughput, and durability. The choice of screen type depends on factors such as the material being processed, desired particle size distribution, and the intended use of the final product.

Material: CS/SS

Hole size:CS0.3-8.0/SS0.6-3.0