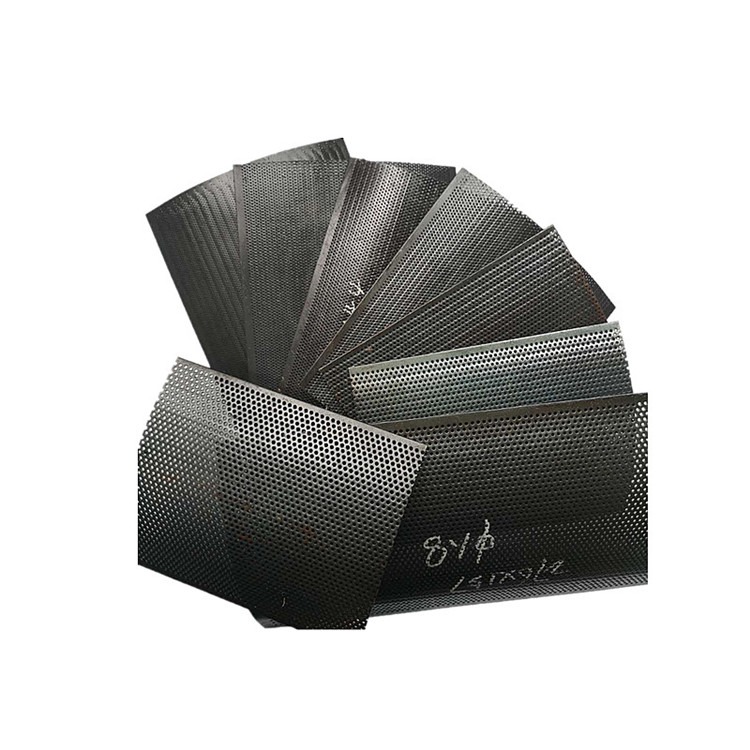

Hammer mill screen for sale

Hammer mill screen for sale

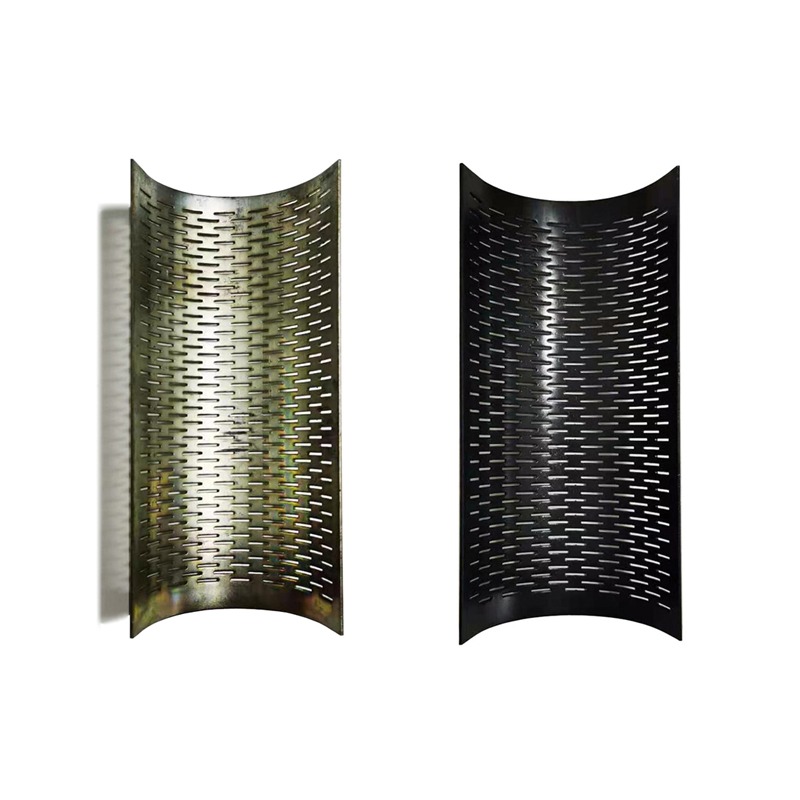

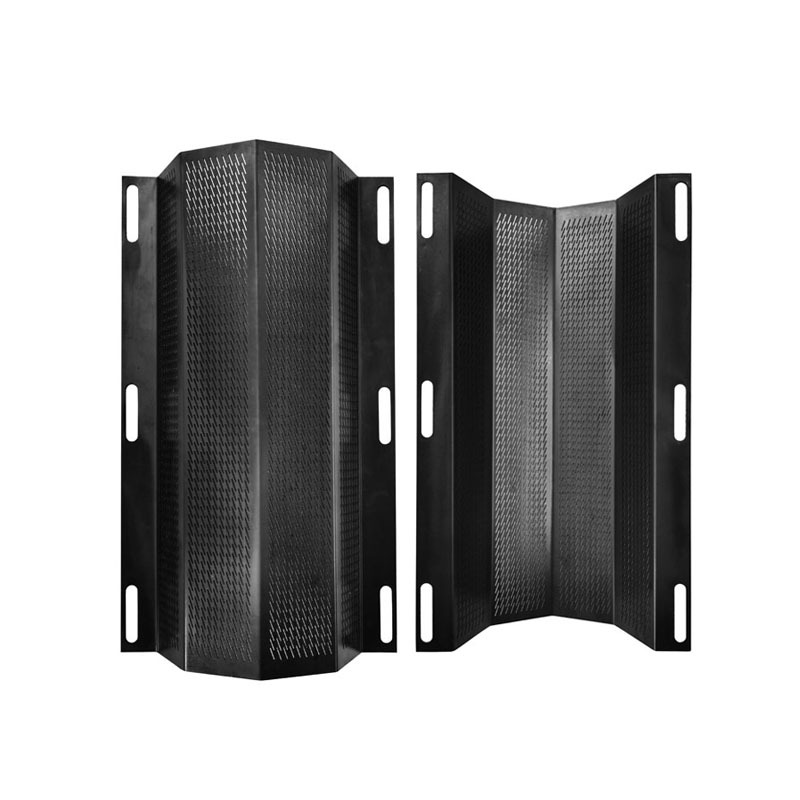

Our factory manufactures a range of essential spare parts for rice mills, including bow screens, hexagonal screens, flat screens, sifters, and more. The main exported series and models encompass SFSP, 40#, 50#,40-20, 350#, 50-25, 40-28, 60*60, 60*45, 63*70, With an annual production capacity of 8 million sets.

Material: CS/SS

Thickness: 0.3-8.0mm

Hole size:CS0.3-8.0/SS0.6-3.0

Dimension: as your request

MOQ: 10-20pcs