- 86-15115027808

- Silvia@agro-greengo.com

- Yueyang Hunan, CN

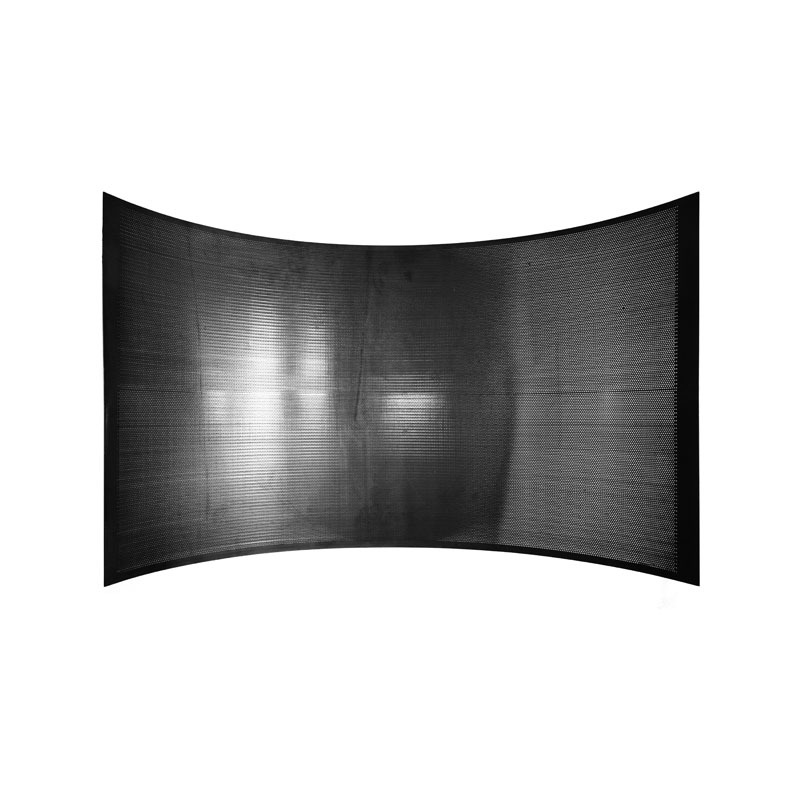

Flour Mill Screen

Hammer mills are commonly used in various industries for grinding and pulverizing materials. The screen in a hammer mill plays a crucial role in controlling the particle size distribution of the ground material.

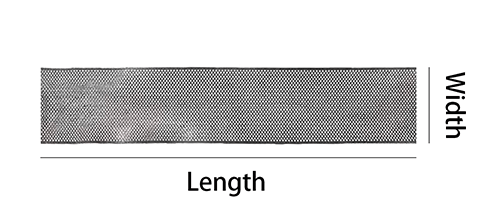

Thickness: 0.3-3.0mm or as your request.

Size: as per your request.

Item name: hammer mill screens for hammer crusher

Material: Carbon steel/ ss201/ ss304/ or as your requirement.

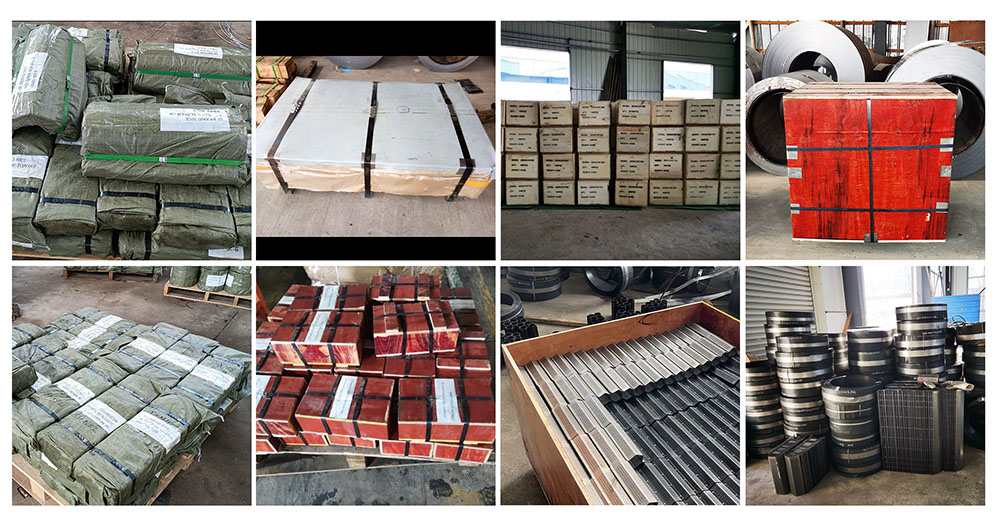

Packing: woven bags/ wooden boxes/pallet packing

Table of Contents

Essential for Many Industries

Flour mill screens are essential components used extensively in industries such as agriculture, chemicals, pharmaceuticals, and food processing. They play a crucial role in converting grains into flour and breaking down raw materials into fine powders or granules. These screens are key to maintaining efficient and effective production processes.

Description

Flour mill screen for maize grinder flour mill mesh flour mill screen for hammer crusher Customized Flour Mill Screen Supplier

Flour mill screens are essential for controlling particle size in various industries, including agriculture, chemicals, pharmaceuticals, and food processing. These durable and efficient screens ensure precise grinding and pulverization.

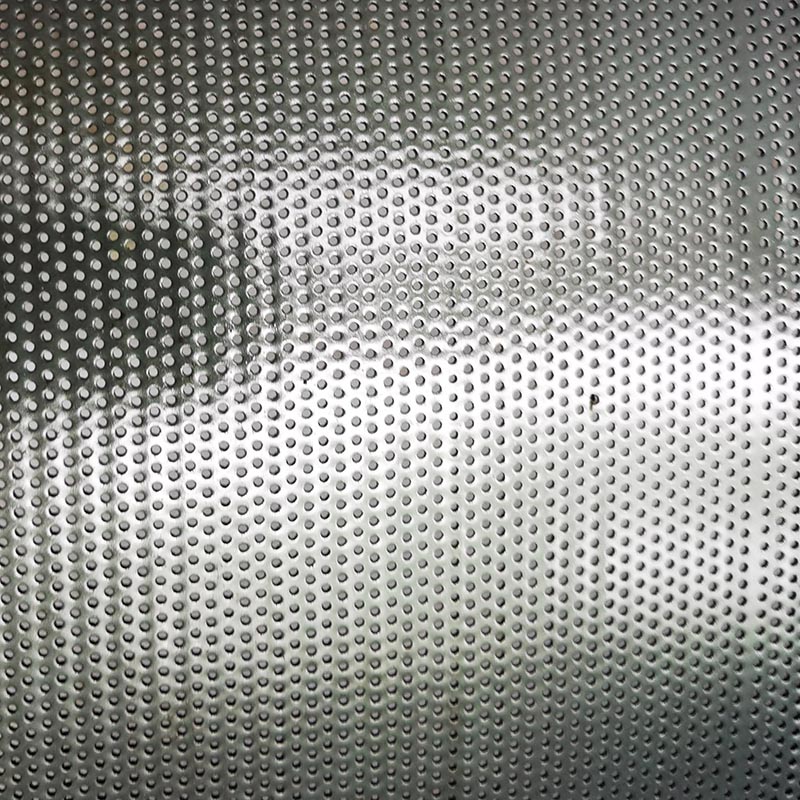

Screen Features:

- Material: Constructed from durable stainless steel or carbon steel for longevity.

- Design: Flat and robust design to prevent deformation during sieving.

- Precision: Engineered with precise slotted holes for accurate filtering.

- Maintenance: Easy to clean, ensuring no rice wastage.

Product Specifications

- Materials: Available in carbon steel and stainless steel.

- Hole Sizes: Ranging from 0.3mm to 8mm. (Stainless steel ranging from 0.6mm)

- Thickness: Options from 0.3mm to 8mm.

- Minimum Order Quantity (MOQ): 20 pieces for standard or in-stock items.

For custom sizes or non-standard products, please contact us for more detailed information.

Here for reference:

Crushing mill screens are indispensable in multiple industries, ensuring precise particle size control. Crafted from high-quality materials with meticulous craftsmanship, they provide stability, efficiency, and reliability in production processes.

Choosing the Right Products for Your Machine

Key Spare Parts for Rice Mill Machines: These parts are essential for brown rice husking, polishing, and whitening, catering to the diverse functions of rice mill machines.

Wide Range of Sieves: We offer sieves compatible with all major brands, including those from Japan, India, China, and others such as Qili, Xiang Xiang, and CLG Gime.

Enhanced Durability: All our products undergo dual heat treatment, resulting in increased hardness and durability.

Variety of Materials: Our screens come in two types: stainless steel and carbon steel. Stainless steel screens, especially those treated with heat, offer superior quality and longer lifespan compared to carbon steel counterparts.

Products related

Packing details

Durable Construction, Precision Engineering

Crushing mill screens are crafted from high-quality metals or durable materials, ensuring stability and longevity even during prolonged usage. Our meticulous craftsmanship guarantees the smoothness and uniformity of the screen surface, facilitating the seamless passage of materials and maintaining consistent particle size distribution.

Tailored Particle Size Control

The precise design of small apertures or perforations on crushing mill screens enables meticulous control over material particle size. With a range of screen sizes and shapes available, we offer tailored solutions to achieve precise particle size control during the grinding process, meeting the diverse production requirements of various products.

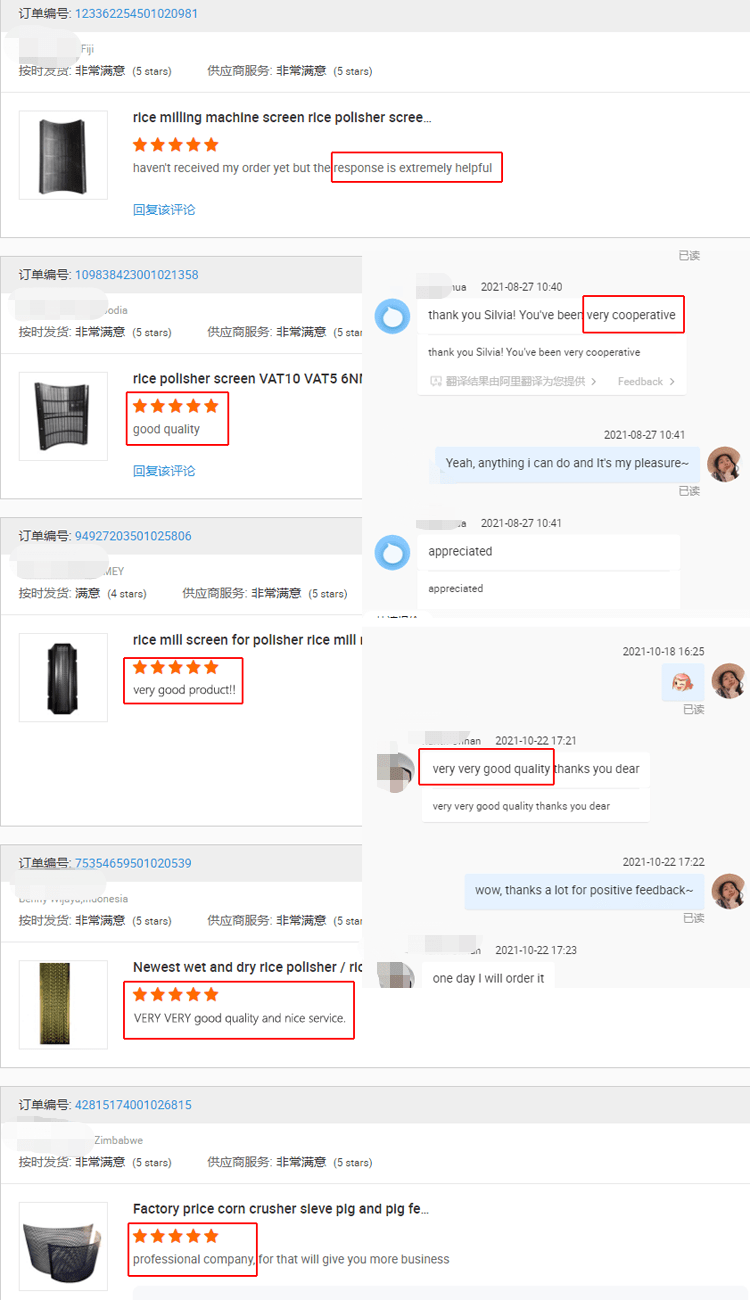

Feedbacks from clients

Address

Wensheng south RD, Yueyang, Hunan, CN

Email Us

silvia@agro-greengo.com

Call/ WhatsApp

+86 15115027808