- 86-15115027808

- Silvia@agro-greengo.com

- Yueyang Hunan, CN

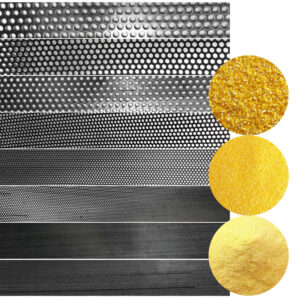

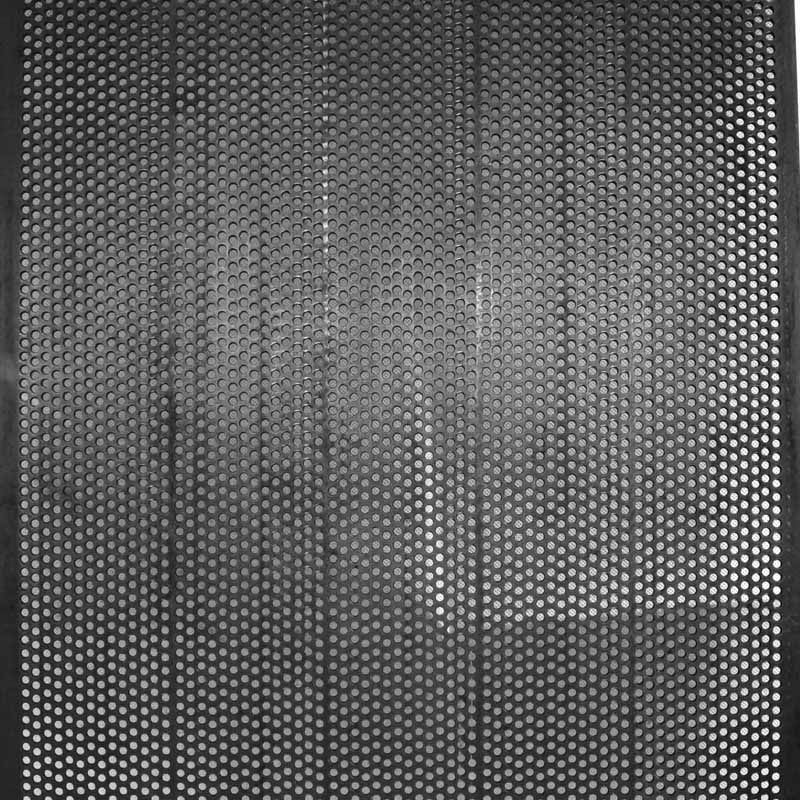

Feed grinder screen

Poultry like chickens and ducks typically require smaller particle sizes compared to larger livestock such as cattle or pigs. This is because poultry have a more efficient digestive system and may struggle to consume larger particles.

Specifically, for chickens, ducks, and fish, the recommended screen sizes can range from 1.0 to 3.0 millimeters, depending on factors such as the age of the animals, the type of feed ingredients used, and the desired feed texture.

Material: Carbon steel/ ss201/ ss304/ as per client require.

Size: as per your request

Table of Contents

Description

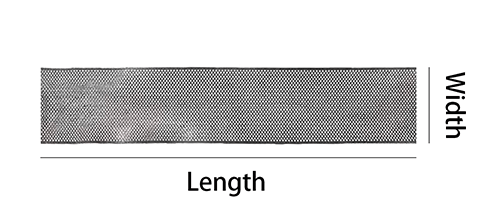

Use the following methods to measure the grinder screens for sale Feed grinder screen hammer mill feed grinder

Use a centimeter ruler to accurately measure the length and width of the sieve.

How to chooing the right feed grinder screen?

Enhancing Feed Processing Efficiency: A Guide to Choosing the Right Feed Grinder Screen

In the world of animal farming and feed production, the choice of feed grinder screens is crucial for achieving high-quality and consistent feed products. Understanding the importance of selecting the correct feed grinder screen is key to optimizing feed processing efficiency.

AGRO-GREENGO: Your Expert in Custom Feed Grinder Screens

At AGRO-GREENGO, we specialize in manufacturing feed grinder screens and offer personalized solutions to meet your specific needs. Whether you require screens of varying sizes, materials, or shapes, we can tailor them to your requirements.

The Significance of Feed Grinder Screens

Feed grinder screens are essential components in feed processing equipment, such as hammer mills and grinders. They regulate the particle size of the feed material, influencing factors like digestibility and nutrient absorption in animals. By ensuring uniform feed texture, grinder screens facilitate mixing and contribute to a well-balanced feed ration.

Key Considerations in Screen Selection

When choosing feed grinder screens, several factors should be considered to maximize processing efficiency:

Particle Size Requirements: Different livestock and production stages require specific feed particle sizes for optimal digestion and nutrient utilization. Selecting screens with the desired mesh size is essential for meeting these requirements.

Feed Ingredient Characteristics: Factors like moisture content, fibrousness, and hardness of feed ingredients affect the grinding process. Screen selection should consider these factors to achieve efficient particle reduction.

Processing Capacity: The throughput capacity of the feed grinder and desired production output determine the screen size and configuration. Balancing particle size reduction with processing speed is crucial for maintaining productivity and feed consistency.

Equipment Compatibility: Ensuring compatibility between the feed grinder and selected screens is vital for optimal performance. Screens should be compatible with the grinder model and correctly installed to prevent inefficiencies and premature wear.

Tailored Solutions for Your Needs

Modern feed processing equipment offers customization options to tailor grinder screens to specific requirements. Manufacturers provide screens with varying mesh sizes, materials, and configurations to accommodate diverse feed formulations and processing objectives. Leveraging these customization options allows feed producers to optimize particle size distribution and enhance feed quality while minimizing processing costs.

Conclusion

Choosing the right feed grinder screens significantly impacts feed processing efficiency. By considering factors like particle size requirements, feed ingredient characteristics, processing capacity, and equipment compatibility, producers can make informed decisions. AGRO-GREENGO‘s personalized solutions ensure that your feed processing needs are met efficiently and effectively.

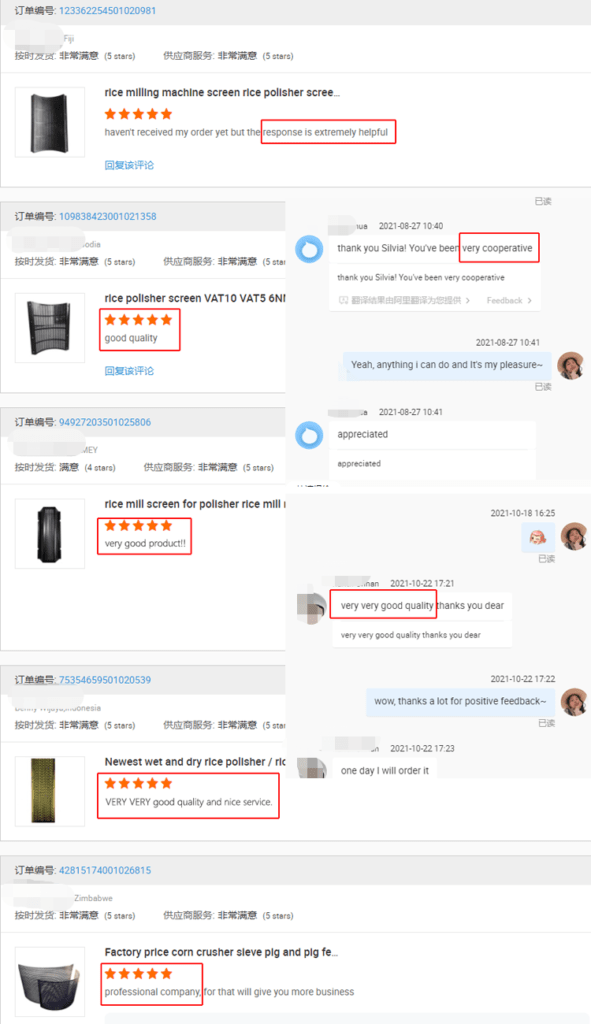

Feedback from clients

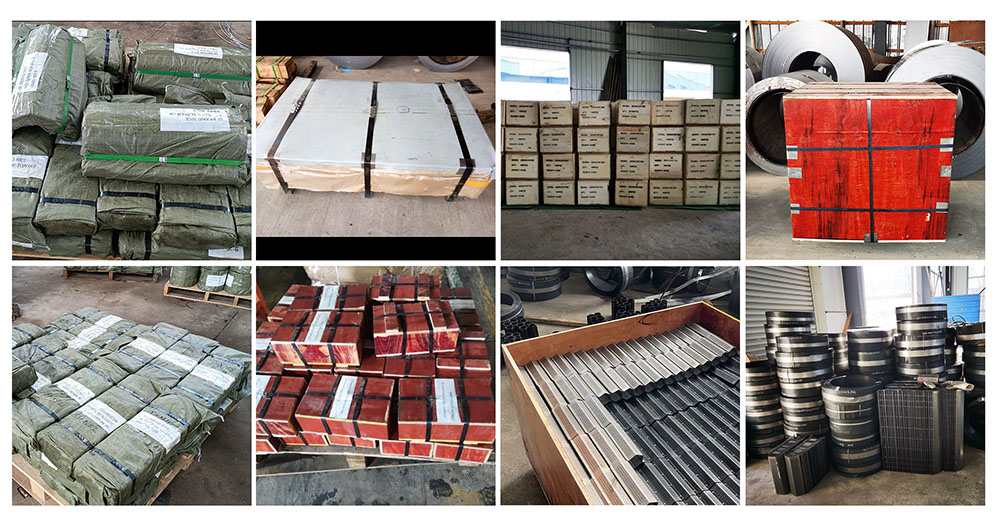

Packaging

How to place an order?

Select the Product:

- Choose the desired items from store.

Place an Order:

- Fill in the order form on our website with the necessary details.

Payment:

- Select a payment method and complete the transaction.

Order Confirmation:

- Receive and confirm the order details.

Shipping:

- We will prepare and ship the items, providing a tracking number.(by air)

- Send it to your agent in China.(by sea or air)

Logistics and Transport:

- Track the shipment to estimate the arrival time.

Customs Processing:

- The items may undergo customs processing upon arrival, and import duties may apply.

Delivery and Receipt:

- Receive the items and pay any additional fees if required.

Inspection:

- Ensure the items are in good condition and meet the specified requirements.

Feedback and After-Sales:

- Provide feedback on the shopping experience and contact us if issues arise.

Address

Wensheng south RD, Yueyang, Hunan, CN

Email Us

silvia@agro-greengo.com

Call/ WhatsApp

+86 15115027808