What is the Best Material for Rice Mill Screens

Choosing the Ideal Material for Rice Mill Screens: A Comparison of Carbon Steel, Mild Steel, Stainless Steel 304, and 201 Selecting the right material for

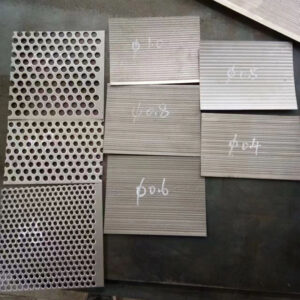

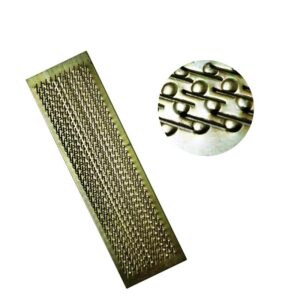

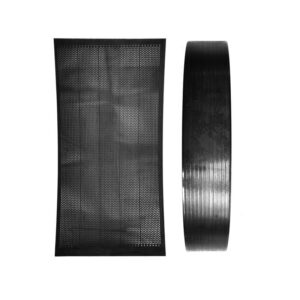

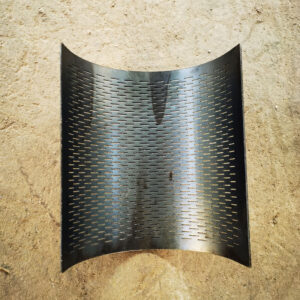

Are you searching for reliable agricultural machine screens to enhance your farm machinery? Look no further! Our advanced sieve types are designed to withstand the toughest conditions, providing durable screening solutions for various agricultural applications. Whether you need high-performance mesh screens for efficient grain sorting or precision agricultural screens for optimal crop handling, we offer a range of specialty sieve options to meet your specific needs. Our products are crafted with quality materials to ensure long-lasting farm equipment parts that deliver exceptional performance. Explore our selection today and discover the difference in quality and durability with our advanced Durable Agricultural Machine Screens.

Process:

Advantages:

Vickers Hardness:

Process:

Advantages:

Vickers Hardness:

Process:

Advantages:

Vickers Hardness:

In the agricultural machinery industry, the durability and performance of screen components are crucial. Surface hardening is a key process to enhance the wear resistance and longevity of these parts. Below, we delve into the main surface hardening methods used for agricultural machinery screens, highlighting their processes, advantages, and the typical Vickers hardness achieved.

The cost of surface hardening treatments varies depending on the method used:

Glow Discharge Nitriding: Generally the most expensive method. It requires advanced equipment and involves a complex low-temperature process.

Carbo-Nitriding: Moderately priced, balancing between advanced and basic treatments. It requires controlled gas environments and precise temperature management.

Surface Quenching: Usually the most cost-effective method. It involves high-temperature heating and rapid cooling, with lower equipment and processing costs compared to advanced methods.

In summary, glow discharge nitriding typically costs more than carbo-nitriding, which in turn is more expensive than surface quenching. The choice of method should consider both performance needs and budget constraints.

Surface Quenching:

Lifespan: More durable than standard heat treatment. Typically used for products like rice screens, flour screens, and polishing screens.

Carbo-Nitriding:

Lifespan: 3 to 5 times more durable than surface quenching. Commonly used for rice screens with apertures larger than 1.0 mm and flour screens.

Glow Discharge Nitriding:

Lifespan: 7 to 9 times more durable than surface quenching. Primarily used for polishing screens due to its exceptional durability.

Most Popular

Choosing the Ideal Material for Rice Mill Screens: A Comparison of Carbon Steel, Mild Steel, Stainless Steel 304, and 201 Selecting the right material for

Always Breaking? Explore Superior Screening Solutions Are you searching for reliable agricultural machine screens to enhance your farm machinery? Look no further! Our advanced sieve

Understanding Hammer Mill Screens: Types, Functions, and Benefits How Hammer Mill Screens Work Hammer mill screens are critical components in the grinding and milling processes

8 Things You Need To Know There are a total of 2 steps for What does a hammer mill do, follow along with the editor

There are a total of 2 steps for What does a hammer mill do, follow along with the editor to take a look! Table of

Table of Contents Milling process for rice Feeding and Cleaning So, What is the milling process for rice? First let’s see grain cleaning machine, also

8437.90 or 8437.80 What is the Hs code for rice mill screen? The Hs code for rice mill screens can vary depending on the specific type

Latest News

Contact Us

Choosing the right surface hardening method for agricultural machinery screens is essential for optimal performance and durability. Here’s a quick overview:

Surface Quenching: This cost-effective option enhances durability compared to untreated screens. It’s ideal for rice screens, flour screens, and polishing screens. While its lifespan is shorter compared to more advanced methods, it still provides significant improvements over non-treated screens.

Carbo-Nitriding: Offers 3 to 5 times greater durability than surface quenching. Perfect for rice screens with larger apertures (over 1.0 mm) and flour screens, balancing performance and cost effectively.

Glow Discharge Nitriding: Provides the highest durability, being 7 to 9 times more enduring than surface quenching. Best suited for polishing screens that require exceptional wear resistance.

For tailored advice and to select the most suitable screens for your needs, contact us today. Our experts can help you choose the right surface hardening treatment to ensure maximum performance and longevity for your agricultural machinery components

Address

Wensheng south RD, Yueyang, Hunan, CN

Email Us

silvia@agro-greengo.com

Call/ WhatsApp

+86 15115027808