What is the Best Material for Rice Mill Screens

Choosing the Ideal Material for Rice Mill Screens: A Comparison of Carbon Steel, Mild Steel, Stainless Steel 304, and 201 Selecting the right material for

Hammer mill screens are critical components in the grinding and milling processes of various materials across industries such as agriculture, food processing, and mining. These screens are designed to fit inside a hammer mill and play a crucial role in determining the particle size of the final product. In this article, we will explore the importance of hammer mill screens and their role in the grinding process.

● Screen Placement and Orientation

Proper placement and orientation of hammer mill screens significantly influence the overall performance of the mill. These screens are positioned inside the grinding chamber, between the hammer rotor and the liner. Their primary function is to control the size and flow of the particles being processed.

The placement of the screen within the hammer mill is crucial for efficient operation. It should be positioned close to the hammer rotor but with enough clearance to allow for proper airflow and particle movement. This ensures effective grinding and prevents blockages or excessive wear on the screens.

Additionally, the orientation of the screens is vital. Most hammer mill screens have a specific pattern or design, such as perforations or holes of varying sizes. These patterns are carefully engineered to optimize the grinding process and achieve the desired particle size distribution.

● Impact on Particle Size Distribution

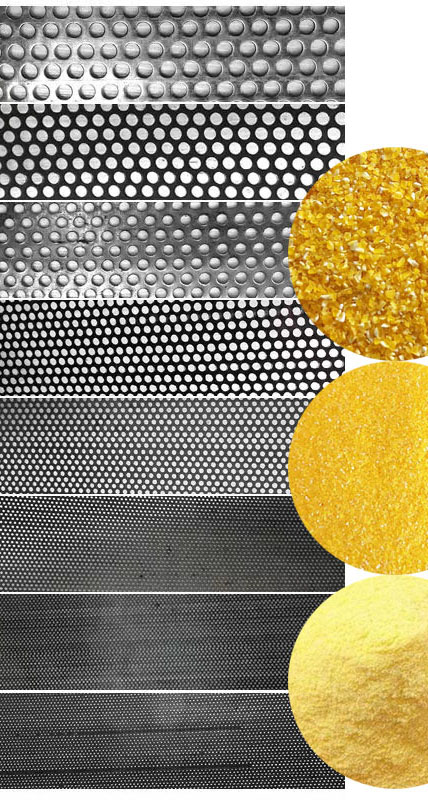

Hammer mill screens greatly impact the particle size distribution of the final product. The size and configuration of the screen perforations determine the size of the particles that can pass through them. Different applications may require specific particle sizes, and the appropriate screen perforations must be selected accordingly.

When material is fed into the hammer mill, it encounters the rotating hammers that strike and grind the particles. The size of the perforations on the screen determines whether the particles will pass through or be retained. Smaller perforations allow finer particles to pass through, resulting in a finer particle size distribution, while larger perforations allow coarser particles to pass through, leading to a coarser distribution.

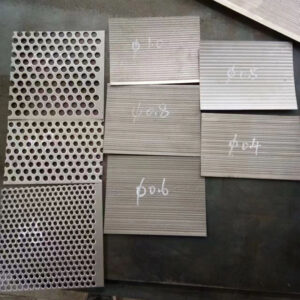

● Influence of Screen Hole Size and Shape

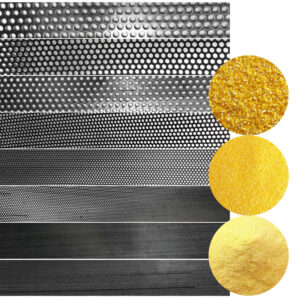

The size and shape of the perforations on hammer mill screens play a crucial role in shaping the grinding process and determining the final distribution of particle sizes.

Screen hole size, referring to the diameter or dimensions of the openings in the screen, is a pivotal factor. It governs the passage of particles through the screen, impacting overall grinding efficiency. Smaller hole sizes yield finer particle sizes, whereas larger hole sizes accommodate coarser particles.

Moreover, the shape of the screen holes significantly affects the grinding dynamics. Variants like round, square, and slotted holes offer distinct advantages, tailored to specific application needs.

● Importance of Open Area Percentage

The open area percentage of hammer mill screens is a pivotal design consideration. It quantifies the proportion of exposed surface area on the screen. A higher open area percentage translates to more space for material passage, enhancing throughput and mitigating blockages.

However, striking a balance between open area percentage and screen robustness is critical. While higher percentages enhance material flow, they may compromise screen durability and lifespan. Manufacturers employ sophisticated methodologies to maintain consistent open area percentages across screen designs by adjusting perforation density and spacing.

A hammer mill stands as a versatile and extensively utilized apparatus for size reduction and grinding across diverse industrial sectors. Gaining insight into the distinct components of a hammer mill is pivotal for grasping its operational intricacies.

Housing Serving as the external casing, the housing envelops and safeguards the internal constituents of the hammer mill. Crafted from robust materials like steel or cast iron, the housing imparts structural integrity and bolsters the integrity of the mill’s framework.

Rotor At the heart of the hammer mill lies the rotor, a central rotating assembly. Comprising a main shaft adorned with an array of hammers, the rotor whirs at accelerated velocities, engendering the requisite impact and grinding actions crucial for size reduction. The design and configuration of the hammers are tailored to specific applications and desired grinding objectives.

Hammer Pins Hammer pins function as the linkage mechanisms, affixing the hammers securely to the rotor. Typically inserted through perforations in the rotor, these pins are firmly fastened to ensure the steadfast positioning of the hammers during operation. Providing stability, they facilitate the efficient transmission of impact forces from the rotor to the hammers.

Hammer Plates Also acknowledged as breaker plates or screen plates, hammer plates line the interior walls of the grinding chamber. Serving as protective shields, they endure the brunt of the materials’ impact during processing. Crafted from diverse materials such as hardened steel or alloys, these plates confer resistance to wear, thereby extending their operational longevity.

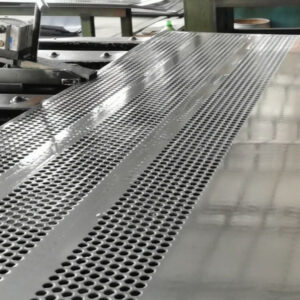

Screen The screen, positioned amidst the rotor and the hammer plates, comprises a perforated metal sheet or wire mesh. Enabling the passage of particles while retaining larger entities within the grinding chamber, the screen’s perforations dictate the ultimate particle size distribution of the resultant product.

Discharge Opening Constituting the egress point for the processed material, the discharge opening is typically situated at the base of the grinding chamber. Its adjustability facilitates the regulation of material flow rates and particle size distributions of the discharged material.

Drive System The drive system, a pivotal component of the hammer mill, encompasses elements such as the motor, pulleys, belts, and bearings. Endowing the mill with power, this system facilitates the rotational movement of the rotor, ensuring the mill’s operational efficiency and seamless functionality.

Feed Inlet Serving as the ingress portal, the feed inlet enables the introduction of material into the grinding chamber. Positioned strategically, it enables uniform and regulated feeding of material into the hammer mill, optimizing processing efficiency.

Numerous leading companies specialize in the production of industrial hammer mills, such as SATAKE, Bühler, and Stedman Machine Company. These manufacturers provide a diverse array of hammer mills tailored with distinct features and advantages to cater to the unique requirements of various industries and applications. A frequently asked question revolves around the comparison between hammer mills and roller mills. Although both serve the purpose of grinding and milling, hammer mills typically excel in efficiency and are adept at achieving finer particle size reduction, while roller mills are more proficient in coarser particle size reduction. Agro-greengo is a factory specializing in hammer mill screens.

Controlling Particle Size:

Hammer mill screens are instrumental in managing the size of processed materials. Manufacturers use varying screen perforations to determine the particle size passing through. This precision is vital for industries requiring specific particle sizes, like animal feed, biomass fuel, and pharmaceuticals.

Enhancing Grinding Efficiency:

These screens are pivotal in maximizing mill efficiency. They ensure uniform distribution of processed material, minimizing uneven wear on internal components. Proper screen design and placement ensure effective particle reduction and consistent product quality.

Oversize Material Prevention:

Oversize material can hinder mill performance. Ineffective screening leads to blockages, reduced throughput, and increased power consumption. Hammer mill screens allow appropriately sized particles to pass while retaining larger ones for further processing.

Flexibility and Adaptability:

Manufacturers leverage hammer mill screens to tailor grinding processes. Various screen hole sizes and shapes facilitate customization, catering to diverse industry needs. This adaptability ensures optimal performance and efficiency across different materials and applications.

Quality Improvement:

Utilizing suitable hammer mill screens contributes to high-quality end products. Controlled particle size distribution ensures consistent product characteristics, essential in industries like food processing and animal nutrition.

Extending Equipment Lifespan:

Hammer mill screens protect internal components from abrasive materials, minimizing wear and tear. By preventing excessive damage, they enhance the reliability and lifespan of hammer mill equipment, leading to cost savings and reduced downtime.

Most Popular

Choosing the Ideal Material for Rice Mill Screens: A Comparison of Carbon Steel, Mild Steel, Stainless Steel 304, and 201 Selecting the right material for

Always Breaking? Explore Superior Screening Solutions Are you searching for reliable agricultural machine screens to enhance your farm machinery? Look no further! Our advanced sieve

Understanding Hammer Mill Screens: Types, Functions, and Benefits How Hammer Mill Screens Work Hammer mill screens are critical components in the grinding and milling processes

8 Things You Need To Know There are a total of 2 steps for What does a hammer mill do, follow along with the editor

There are a total of 2 steps for What does a hammer mill do, follow along with the editor to take a look! Table of

Table of Contents Milling process for rice Feeding and Cleaning So, What is the milling process for rice? First let’s see grain cleaning machine, also

8437.90 or 8437.80 What is the Hs code for rice mill screen? The Hs code for rice mill screens can vary depending on the specific type

Latest News

Contact Us

The size and quality of the screens directly influence screening efficiency and durability. Well-designed screens are crucial for optimal performance.

Screens adhere to strict standards regarding hole sizes and classifications, ensuring compatibility with industry regulations and standards.

Higher opening ratios in screens correlate with increased production capacity for the pulverizer, enhancing overall efficiency.

Larger effective use areas in screens translate to higher efficiency in screening operations, promoting smoother processing.

Heat treatment enhances the wear resistance of screens, prolonging their service life and reducing the frequency of replacements.

The selection of screen opening sizes depends on the desired particle size. It’s advisable to choose screens with the largest aperture feasible, considering the strength and requirements of the sieves.

In summary, hammer mill screens play a vital role in the grinding and milling of diverse materials. It’s crucial to comprehend their design and functionality to choose the suitable screen for specific applications. Collaborating with reputable manufacturers enables industries to select the appropriate hammer mill to attain the desired particle size in their end products.

For any further requirements, feel free to reach out to us!

Address

Wensheng south RD, Yueyang, Hunan, CN

Email Us

silvia@agro-greengo.com

Call/ WhatsApp

+86 15115027808