What does a hammer mill do?

Table of Contents

Hammer mill machine inner structure

Hammer mill

This article primarily discusses the modern hammer mill machine. For historical mills utilizing trip hammers, please refer to the Hammer mill. For the paper manufacturing company, see Hammermill Paper Company.

A hammer mill for milling grain A hammer mill is a mill designed to shred or crush aggregate material into smaller pieces by the repeated blows of small hammers. These machines have numerous industrial applications, including:

Ethanol plants (grains) Farm machinery, which mills grain into coarse flour for livestock feed Defiberizing fluff pulp Fruit juice production Grinding used shipping pallets for mulch Milling grain Production of livestock, poultry, and aquatic feed Size reduction of trim scrap and planer shavings into boiler fuel or mulch in sawmills A desktop hammer mill used for preparing growth media in a life sciences laboratory Shredding paper Shredding scrap automobiles (see automotive shredder residue) Shredding yard and garden waste for composting Crushing large rocks In waste management

The fundamental concept is simple. A hammer mill comprises a robust steel drum housing a vertical or horizontal rotating shaft or drum, equipped with mounted hammers. These hammers can freely swing at the ends of the cross or be fixed to the central rotor. As the rotor spins at high speed within the drum, materials are introduced through a feed hopper. Upon entering, the material is subjected to the forceful impact of the hammer bars, resulting in its shredding and subsequent expulsion through screens of specific sizes located in the drum.

The versatility of the hammer mill extends its utility beyond mere shredding. It can function as a primary, secondary, or tertiary crusher, adapting to various industrial needs.

Hammer mills designed for processing small grains can operate using household electrical current. Conversely, larger hammer mills utilized in automotive shredders may rely on diesel or electric motors with power outputs ranging from 2000 to over 5000 horsepower (1.5 – 3.7MW).

An innovative variation, the screenless hammer mill, utilizes air flow to segregate small particles from larger ones. This design not only enhances reliability but also boasts cost-effectiveness and improved energy efficiency compared to conventional hammer mills. Ultimately, the design and configuration of a hammer mill are tailored to suit its intended application and end use.

Types of Hammer Mill Crushers

Hammer mill crushers come in various types, including “up running” and “down running” configurations.

“Up running” mills utilize perforated screens or grate bars to reduce materials, adjusting rotor construction based on wear.

“Down running” mills are ideal for fibrous materials, offering high shearing action.

Hammer mills are further classified based on motor direction:

- Reversible hammer mills

- Non-reversible hammer mills

While these mills share similar working and grinding actions, their construction varies.

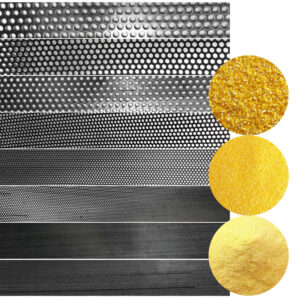

Types of Hammer Mill Crusher screens

Hammermill

overview-From Wikipedia

Related Posts

What is the Best Material for Rice Mill Screens

Choosing the Ideal Material for Rice Mill Screens: A Comparison of Carbon Steel, Mild Steel, Stainless Steel 304, and 201 Selecting the right material for

What are the different methods of surface hardening?

Always Breaking? Explore Superior Screening Solutions Are you searching for reliable agricultural machine screens to enhance your farm machinery? Look no further! Our advanced sieve

How Hammer Mill Screens Work

Understanding Hammer Mill Screens: Types, Functions, and Benefits How Hammer Mill Screens Work Hammer mill screens are critical components in the grinding and milling processes

What is the crushing and screening process

8 Things You Need To Know There are a total of 2 steps for What does a hammer mill do, follow along with the editor

What does a hammer mill do?

There are a total of 2 steps for What does a hammer mill do, follow along with the editor to take a look! Table of

What is milling process for rice?

Table of Contents Milling process for rice Feeding and Cleaning So, What is the milling process for rice? First let’s see grain cleaning machine, also