- 86-15115027808

- Silvia@agro-greengo.com

- Yueyang Hunan, CN

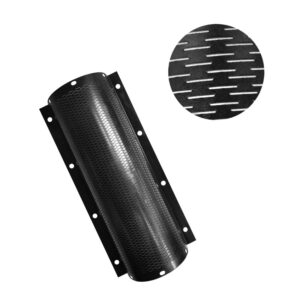

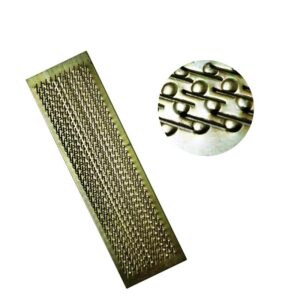

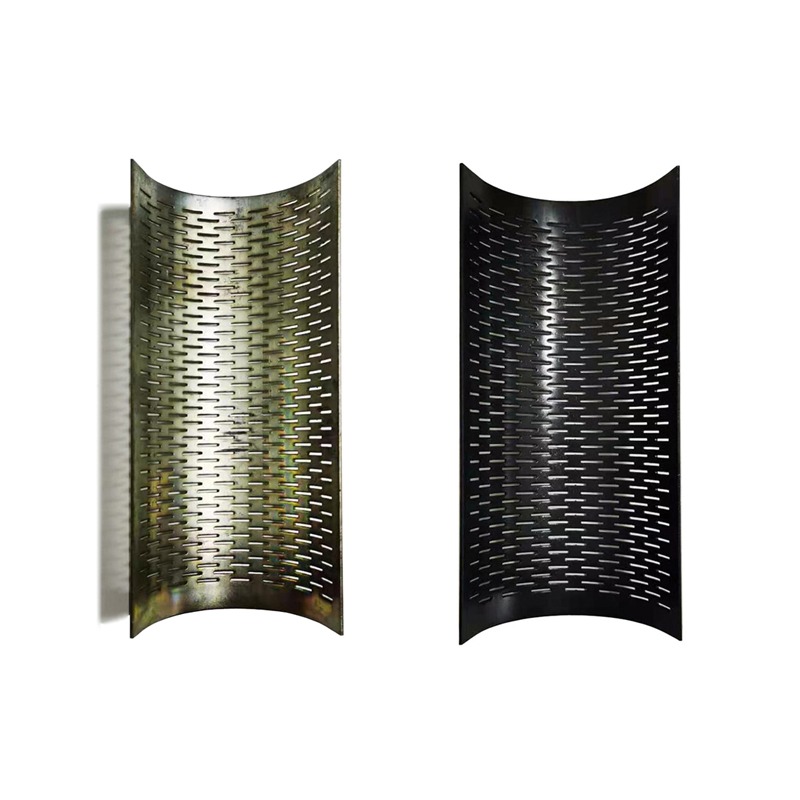

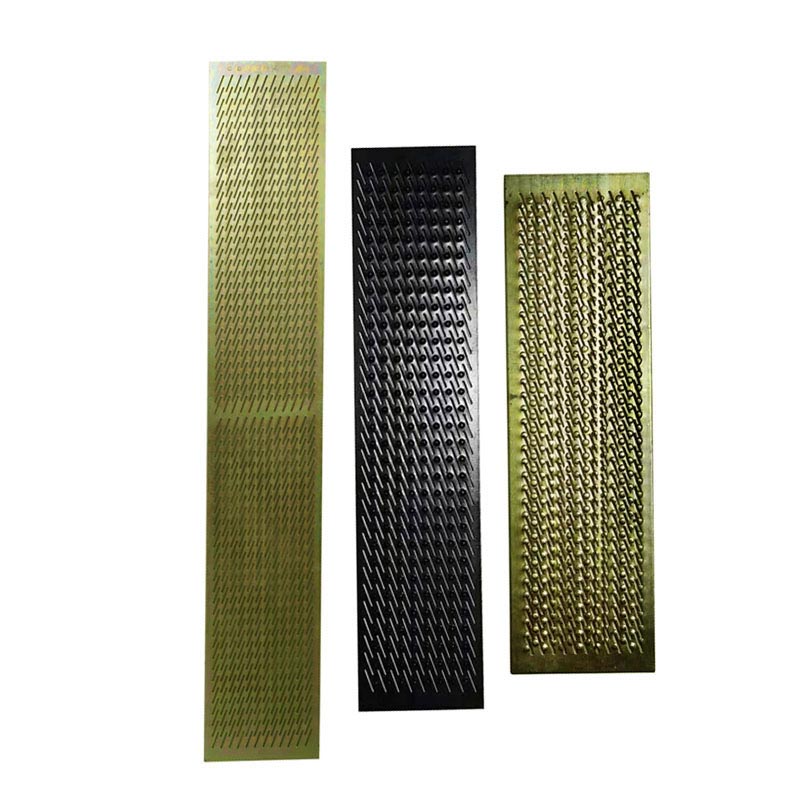

Screen for rice mills

Product Name: Screen for rice mill

Thickness: Ranging from 0.3mm to 5.0mm, tailored to meet your precise specifications.

Size: Fully customizable to accommodate your unique requirements.

Material: Select from a variety of options including carbon steel, SS201, SS304, or personalized materials to meet your exact needs.

Packaging: Choose from woven bags, wooden boxes, pallet packing, or customized packaging solutions to suit your preferences.

Table of Contents

Description

What material is used for rice mill screens?

Mild Steel Materials: q235 carbon steel

Stainless Steel Materials: SS304/SS201

What is the main process of rice milling?

The main process of rice milling includes:

Cleaning: Removing impurities, such as stones, husks, and other foreign materials, from the raw paddy.

Husking: Removing the outer husk or hull from the paddy to obtain brown rice.

Whitening: Removing the bran layer from the brown rice to produce white rice.

Polishing: Further refining the surface of the white rice grains to improve appearance and texture.

Grading: Sorting the milled rice into different grades based on size, shape, and quality.

Packaging: Packaging the graded rice into bags or containers for distribution and sale.

These steps constitute the primary process of rice milling, transforming raw paddy into finished rice suitable for consumption or further processing.

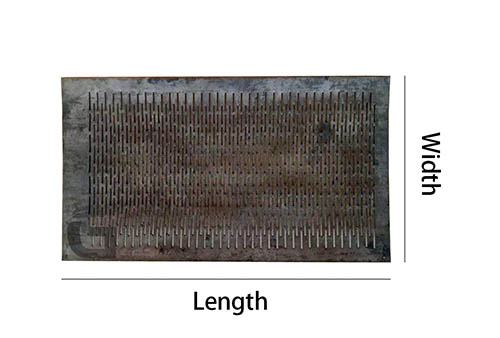

How to measure the screen of rice mills? screen for rice mills

Use the following methods to measure the screen rice mill:

- Spread out the perforated steel sheet to make it flat

- Use a centimeter ruler to accurately measure the length and width of the screen for rice mill

What Are The Main Components Of A Rice Mill? What are the parts of a rice mill?

The Main Components of a Rice Mill: Exploring Key Elements for Optimal Production:

The parts of a rice mill are essential for efficient production. They include the milling chamber, rollers (such as sand roller and iron roller), supply device, and cleaning and cooling rice device. Understanding these components is crucial for maximizing productivity in rice milling operations.

Our advantages

Packaging

How to place an order?

Selecting the Product:

Browse our store and choose the desired items.

Place the order:

Get in touch with us to discuss the detailed product requirements.

Payment:

Select a payment method and complete the transaction securely.

Order Confirmation:

Receive confirmation of your order details.

Shipping:

We will prepare and ship the items, providing a tracking number for air shipments. For sea or air shipments to your agent in China.

Logistics and Transport:

Track the shipment to estimate the arrival time.

Customs Processing:

The items may undergo customs processing upon arrival, with potential import duties.

Delivery and Receipt:

Receive the items and pay any additional fees if required.

Inspection:

Ensure the items are in good condition and meet your specified requirements.

Feedback and After-Sales:

Share your feedback on the shopping experience and contact us for any post-purchase assistance.

FAQ

Q: Quality guarantee?

- A: Manufactured from premium-grade steel and subjected to advanced heat treatment processes for superior performance. You can trust in the quality assurance of all our products.

Q: How to select the perfect product?

- A: Simply provide us with your machine model or specifications, and we’ll guide you through the selection process. Alternatively, refer to the manual or share your requirements for personalized recommendations.

Q: Accepted payment methods?

- A: We accept payments via T/T, Western Union, or MoneyGram for your convenience.

Q: What’s the estimated delivery time?

- A: Small orders typically ship within 7-15 days, while bulk orders are usually dispatched within 30-60 days upon confirmation. Rest assured, we prioritize timely delivery to meet your needs.

Address

Wensheng south RD, Yueyang, Hunan, CN

Email Us

silvia@agro-greengo.com

Call/ WhatsApp

+86 15115027808