- 86-15115027808

- Silvia@agro-greengo.com

- Yueyang Hunan, CN

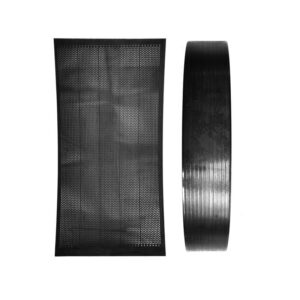

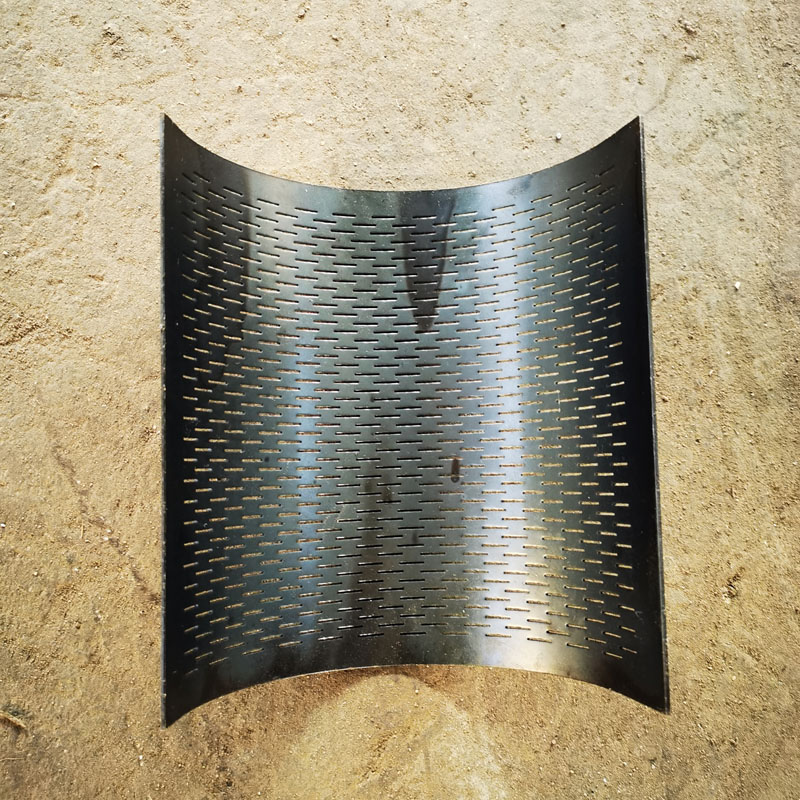

Mini rice mill screen

Product Name: Mini Rice Mill Screen

Thickness: Ranging from 0.3mm to 5.0mm, tailored to meet your precise specifications.

Size: Fully customizable to accommodate your unique requirements.

Material: Select from a variety of options including carbon steel, SS201, SS304, or personalized materials to meet your exact needs.

Packaging: Choose from woven bags, wooden boxes, pallet packing, or customized packaging solutions to suit your preferences.

Table of Contents

Description

Durable Mini rice mill screens from rice mill screen manufacturer:

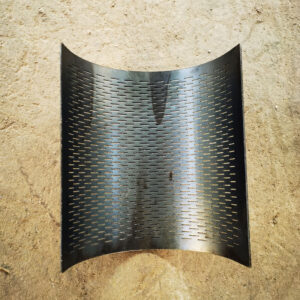

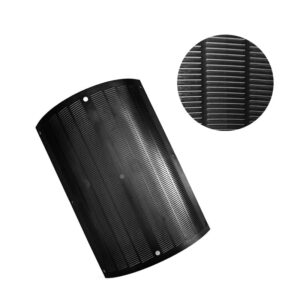

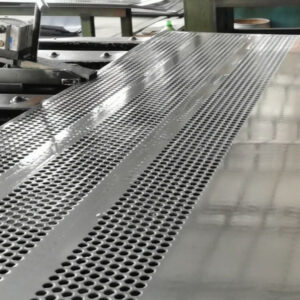

Screen Types: Our rice mill screens come in two types: straight and slanted perforations, offering versatility for diverse grain separation needs.

Aperture Sizes: With aperture sizes ranging from 0.5mm to 1.2mm, our screens provide flexibility to match specific milling requirements.

Material Quality: Crafted from premium materials like carbon steel or stainless steel, our screens are built to last, ensuring durability even under demanding milling conditions.

Heat Treatment: Through carburizing heat treatment, our screens undergo a process that enhances durability, ensuring longevity in continuous operation.

Precision Engineering: Meticulously engineered for precise grain separation, our screens provide the accuracy required for consistent grain quality.

Flexibility: Whether you need fine or coarse milling, our screens offer the versatility to meet your specific grain size requirements.

Reduced Downtime: With a focus on durability and performance, our screens minimize downtime and maintenance costs for rice mill operators, offering a cost-effective solution.

In conclusion, our rice mill screens combine precision engineering, durability, and versatility to optimize grain separation in rice milling operations, enhancing efficiency and productivity worldwide.

Our company specializes in offering a wide selection of high-quality grain sieves and screens, specifically catering to the rice milling industry. From rice mill screens available for sale to perforating services and rice processing screens, we provide comprehensive solutions to enhance the efficiency and quality of rice processing operations. Trust us for reliable products designed to meet the diverse needs of rice mill operators, here for reference:

grain sieves and screens rice mill screen for sale rice mill screen perforating Rice processing screen Rice mill sieves

How is the husk removed from grains?

Removing the husk from grains can be achieved through various methods, depending primarily on the type of grain, scale of production, and desired end product. Here are some common methods:

Manual Husking: For small-scale production or traditional rural areas, manual husking may be chosen. This involves using tools such as rods or sticks to separate the grains from the husks. While manual husking is time-consuming and labor-intensive, it is suitable for small quantities of grain processing.

Mechanical Husking: With technological advancements, many places employ mechanized husking methods. This approach utilizes various equipment such as threshers or dehullers to separate the grains from the husks through methods like agitation, friction, or impact. Mechanical husking generally offers higher efficiency and is suitable for large-scale agricultural production.

Winnowing: Winnowing is a simple yet effective husking method. By tossing a mixture of grains and husks into the air, the wind blows away the lighter husks while the heavier grains fall back into a container. This method, known as winnowing, is commonly used in traditional rural settings.

Chemical Treatment: In some industrialized production processes, chemical substances may be used to soften or dissolve the husks, making them easier to remove mechanically.

Soaking Treatment: For some grains like barley, they may need to be soaked in water first to soften the husk. Subsequently, the grains are separated from the husks manually or mechanically.

Overall, removing the husk from grains can be accomplished through manual methods, mechanization, winnowing, chemical treatment, or soaking treatment, depending on production requirements, technological capabilities, and available resources.

Our advantages

Packaging

How to place an order?

Select the Product:

- Choose the desired items from store.

Place an Order:

- Fill in the order form on our website with the necessary details.

Payment:

- Select a payment method and complete the transaction.

Order Confirmation:

- Receive and confirm the order details.

Shipping:

- We will prepare and ship the items, providing a tracking number.(by air)

- Send it to your agent in China.(by sea or air)

Logistics and Transport:

- Track the shipment to estimate the arrival time.

Customs Processing:

- The items may undergo customs processing upon arrival, and import duties may apply.

Delivery and Receipt:

- Receive the items and pay any additional fees if required.

Inspection:

- Ensure the items are in good condition and meet the specified requirements.

Feedback and After-Sales:

- Provide feedback on the shopping experience and contact us if issues arise.

FAQ

Q: Quality assurance?

A: Crafted from high-quality steel, undergo advanced heat treatment for excellence. Rest assured, all products are quality assured.

Q: Choosing the right product?

A: Provide machine model/specs; we’ll assist. Refer to manual or share requirements for tailored recommendations.

Q: Payment method?

A: Accept T/T, Western Union, or Moneygram.

Q: Delivery time?

A: Small orders ship in 7-15 days; bulk orders within 30-60 days after confirmation.

Address

Wensheng south RD, Yueyang, Hunan, CN

Email Us

silvia@agro-greengo.com

Call/ WhatsApp

+86 15115027808