- 86-15115027808

- Silvia@agro-greengo.com

- Yueyang Hunan, CN

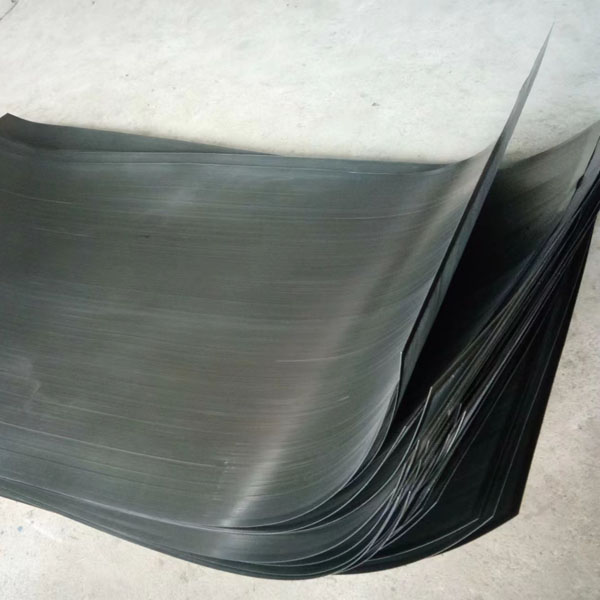

Maize mill screen for crusher machine

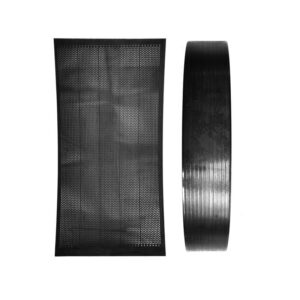

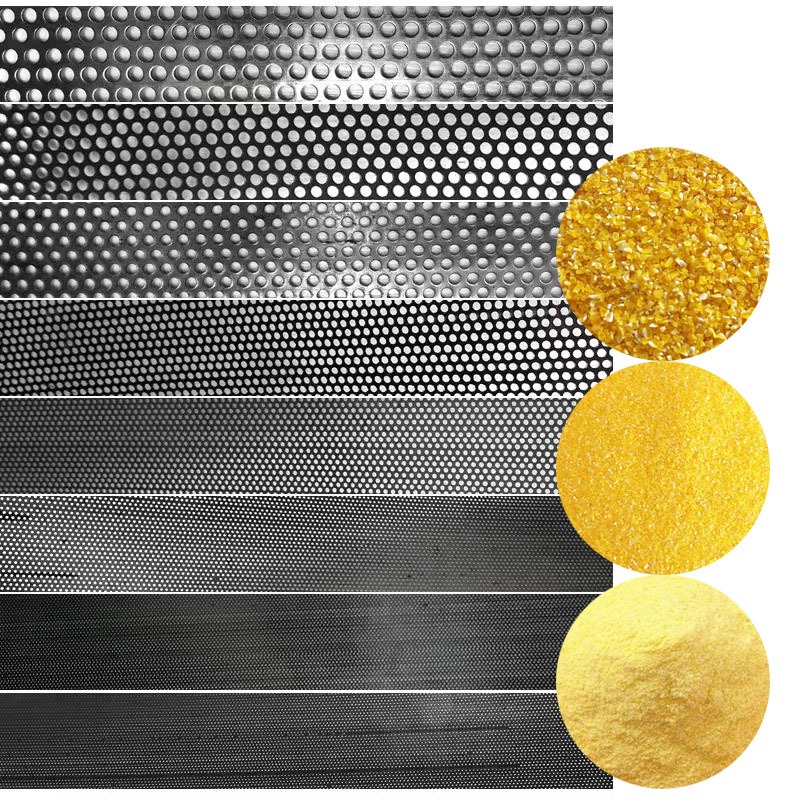

A ‘Maize mill screen’ is an essential component of a hammer mill, a type of grinding machine used in maize processing. It typically consists of a perforated metal plate or wire mesh positioned at the bottom of the mill. Strategically placed, the screen controls the particle size during the grinding or shredding process, ensuring the desired final product consistency. By allowing only particles of a specific size to pass through, it regulates the particle size distribution, while larger particles are retained for further processing.

Specifications:

- Size: Available in standard size of 1×2 meters or can be customized as per client’s request.

- Item Name: Maize Mill Screen for Crusher Machine

- Material: Constructed from high-quality carbon steel or stainless steel (ss201/ss304) according to client’s requirements.

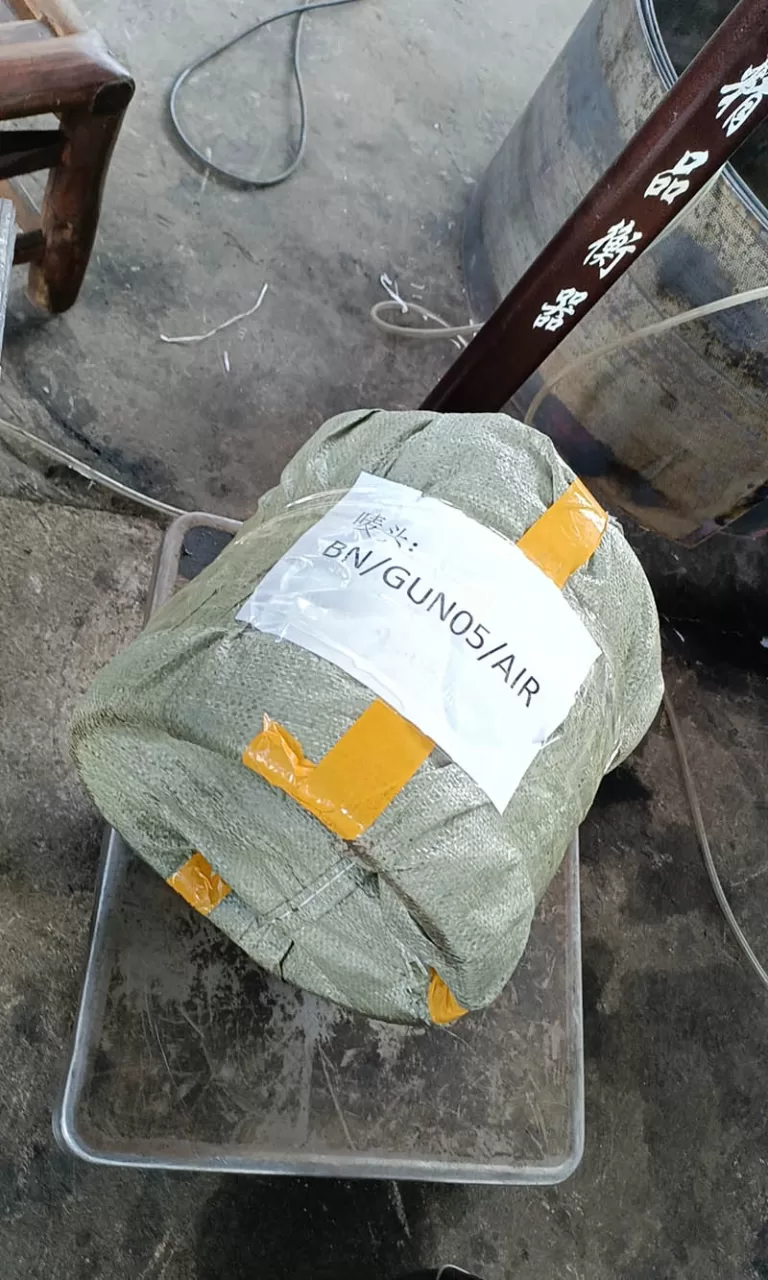

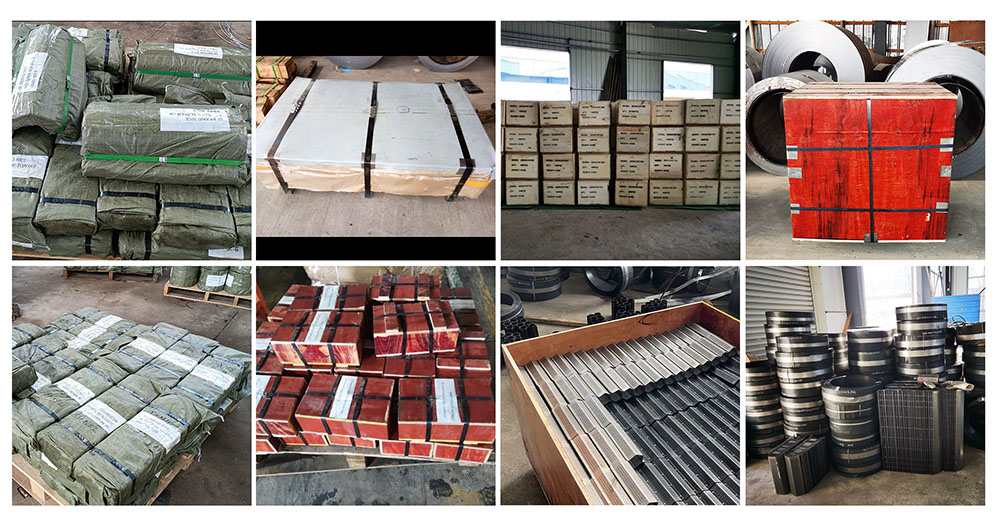

- Packaging: Packaged in woven bags or wooden boxes, tailored to meet client’s specific packaging preferences.”

Table of Contents

Description

Use the following methods to measure the screen hammer mill

Spread out the perforated steel sheet to make it flat.

Use a centimeter ruler to accurately measure the length and width of the sieve.

Selecting the Proper Hammer Screen Size: A Simple Guide for Optimal Results

Introduction: The choice of the right screen size is paramount for efficient processing. Whether employing a hammer mill or a vibrating screen, this straightforward guide aids in making informed decisions for superior outcomes.

Understand Your Material: Familiarize yourself with your material’s characteristics. Factors such as particle size, moisture content, and abrasiveness dictate the appropriate screen size.

Define Particle Size Requirements: Determine the desired particle size. Finer screens are suitable for smaller particles, whereas coarser screens are preferable for larger ones, directly impacting the quality of your end product.

Assess Capacity Requirements: Consider the volume of material being processed. Opting for larger screens may be necessary to handle higher material volumes efficiently.

Review Equipment Specifications: Refer to your equipment’s specifications. Manufacturers typically provide recommendations for screen sizes based on equipment design and intended application.

Conduct Trial Runs: Perform test runs to ascertain the optimal screen size. Experiment with different screens to observe the resulting particle size distributions.

Consider Material Application: Evaluate the intended use of your material. Industry standards and quality requirements may influence the selection of the appropriate screen size.

Balance Energy Consumption: Strike a balance in energy usage. Avoid excessively fine screens, which can lead to energy wastage, or overly coarse screens, which may compromise efficiency.

Seek Expert Advice: When uncertain, consult with industry experts or the equipment manufacturer. Their expertise can offer valuable insights to facilitate decision-making.

Conclusion: Optimal screen size selection hinges on informed decision-making. Follow these straightforward guidelines to maximize the effectiveness of your screening process.

Selecting the Right Products for Your Machine and Hammer Mill Screen Sizes

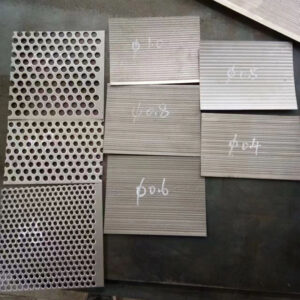

Material Options: Choose between carbon steel or stainless steel for your hammer mill screen, depending on your specific requirements.

Hole Size Range: Our screens are available with hole sizes ranging from 0.3mm to 8mm, allowing you to tailor the screen to your desired particle size specifications.

Thickness Variation: Screens come in various thicknesses, ranging from 0.3mm to 8mm, ensuring durability and optimal performance for your application.

Minimum Order Quantity (MOQ): For standard or stock products, our MOQ is 20 pieces.

Custom Orders: If you require non-standard products or custom sizes, please don’t hesitate to contact us for detailed information. We’re here to accommodate your unique needs and specifications.

Our advantages

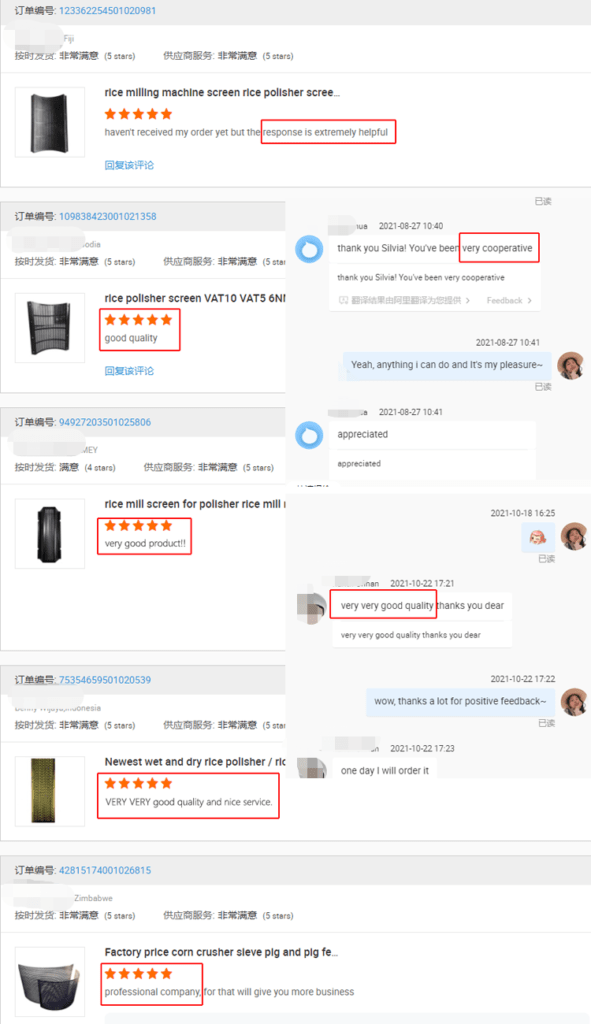

Feedback from clients

Packaging

How to place an order?

Order Placement Process:

Product Selection:

- Browse our store and choose the desired items.

Placing an Order:

- Fill out the order form on our website, providing all necessary details.

Payment:

- Select a preferred payment method and complete the transaction securely.

Order Confirmation:

- Receive an order confirmation with all the details provided.

Shipping:

- We’ll promptly prepare and ship the items, providing a tracking number for air shipments.

- Alternatively, for shipments to China, we can send the items via sea or air to your agent.

Logistics and Transportation:

- Track the shipment to estimate its arrival time accurately.

Customs Processing:

- Upon arrival, the items may undergo customs processing, and import duties may be applicable.

Delivery and Receipt:

- Receive the items and settle any additional fees if required.

Inspection:

- Inspect the received items to ensure they’re in good condition and meet your specified requirements.

Feedback and After-Sales Support:

- Provide feedback on your shopping experience.

- Feel free to contact us if any issues arise post-delivery; we’re here to assist you.

Products related

Address

Wensheng south RD, Yueyang, Hunan, CN

Email Us

silvia@agro-greengo.com

Call/ WhatsApp

+86 15115027808