- 86-15115027808

- Silvia@agro-greengo.com

- Yueyang Hunan, CN

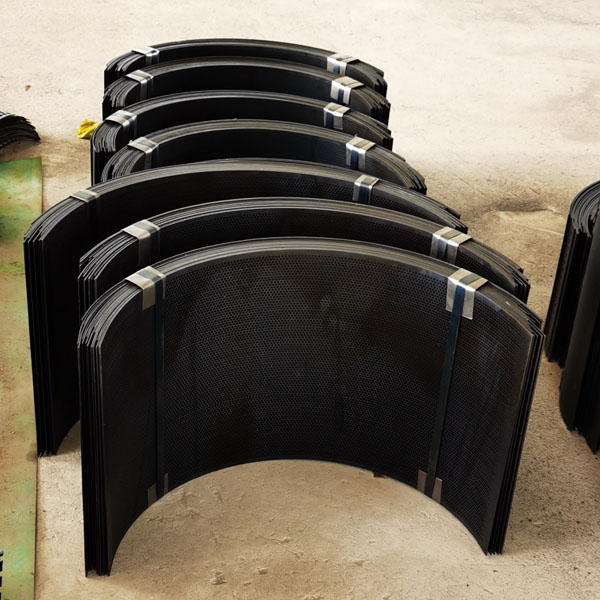

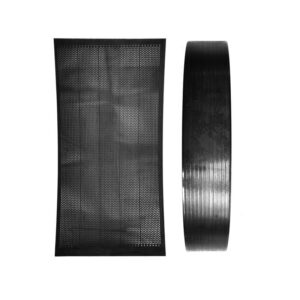

Grain mill screen

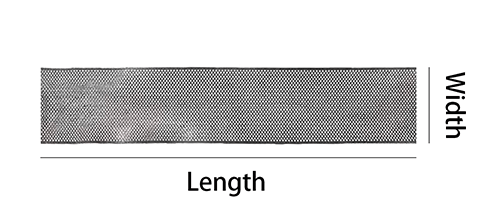

Size: 1000*70/1000*90/1000*2000mm or as per your request.

Item name: Grain mill screen

Material: Carbon steel/ ss201/ ss304/ as per client’s requirement.

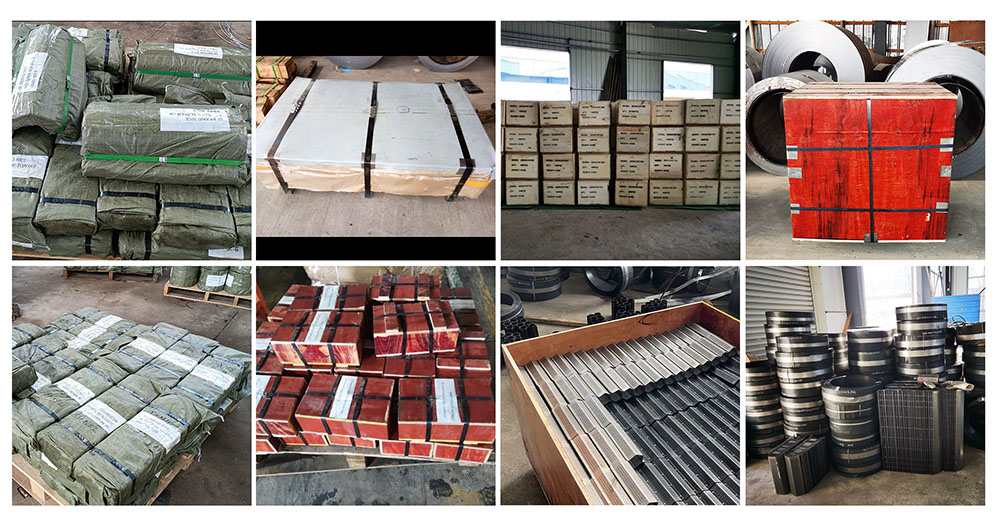

Packing: woven bags/ wooden boxes are per the client’s requirements.

Table of Contents

Description

Looking for top-quality grain milling accessories? Our industrial milling screens, replacement screens for grain mills, and grain sieving screens are just what you need. Our mesh screens for grain mills ensure efficient grain milling operations, delivering consistent results every time. Whether you require replacement screens or other grain mill parts and accessories, we’ve got you covered. Trust us for all your grain milling needs!

How to Select the Proper Screen Size?

Choosing the perfect screen size is crucial for getting the best results from your processing equipment. Whether you’re using a hammer mill or a vibrating screen, here’s a simple guide to help you make the right choices without all the technical jargon:

Know Your Stuff: Understand what you’re working with. Different materials need different screen sizes depending on how big they are, how wet they are, and how rough they might be.

Size Matters: Decide how big or small you want your particles to be. If you need them tiny, go for a fine screen. If you’re after bigger bits, a coarser screen is your go-to.

Think Capacity: Consider how much stuff you’re dealing with. If it’s a lot, you might need a bigger screen to handle it all efficiently.

Check the Manual: Look at what the equipment manufacturer suggests. They usually have recommendations for which screen sizes work best with their machines.

Test, Test, Test: Experiment with different screens to see what works best for your material. Try out a few options and see how the particles turn out.

Keep Usage in Mind: Think about how your material will be used afterward. Certain industries have standards for particle size, so you’ll want to match that.

Save Energy: Don’t waste power on screens that are too fine or too coarse. Find a balance that gets the job done without gobbling up too much electricity.

Get Advice: When all else fails, ask the experts. They can give you tips and tricks to make sure you’re picking the right screen size for your needs.

In a nutshell, picking the right screen size is all about making smart decisions. Follow these simple steps, and you’ll be on your way to better results in no time.

Choosing the Right Products for Your machine and get the hammer mill screen sizes

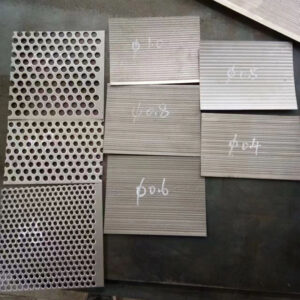

- Material: We offer screens made of carbon steel or stainless steel.

- Hole Size: Our screens come in a range of hole sizes from 0.3mm to 8mm.

- Thickness: You can choose screens with thicknesses ranging from 0.3mm to 8mm.

- Minimum Order Quantity (MOQ): For standard or stock products, the minimum order quantity is 20 pieces.

- Custom Orders: If you need non-standard products or custom sizes, just reach out to us, and we’ll provide you with all the details you need.

Our advantages

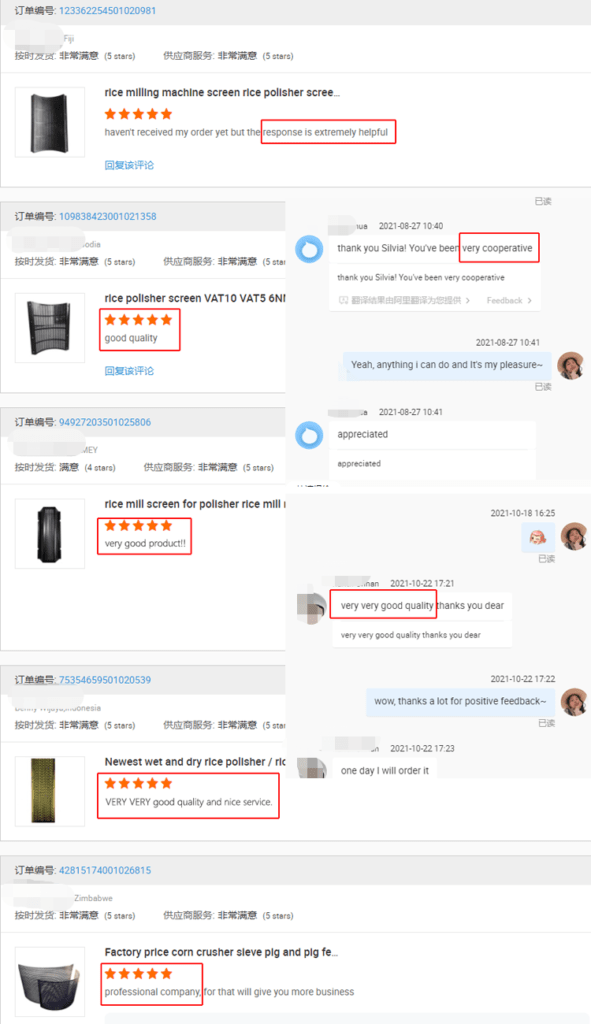

Feedback from clients

Packaging

How to place an order?

Select the Product:

- Choose the desired items from store.

Place an Order:

- Fill in the order form on our website with the necessary details.

Payment:

- Select a payment method and complete the transaction.

Order Confirmation:

- Receive and confirm the order details.

Shipping:

- We will prepare and ship the items, providing a tracking number.(by air)

- Send it to your agent in China.(by sea or air)

Logistics and Transport:

- Track the shipment to estimate the arrival time.

Customs Processing:

- The items may undergo customs processing upon arrival, and import duties may apply.

Delivery and Receipt:

- Receive the items and pay any additional fees if required.

Inspection:

- Ensure the items are in good condition and meet the specified requirements.

Feedback and After-Sales:

- Provide feedback on the shopping experience and contact us if issues arise.

Address

Wensheng south RD, Yueyang, Hunan, CN

Email Us

silvia@agro-greengo.com

Call/ WhatsApp

+86 15115027808